Re-Oxyde

UPCYCLING OF IRON OXIDES

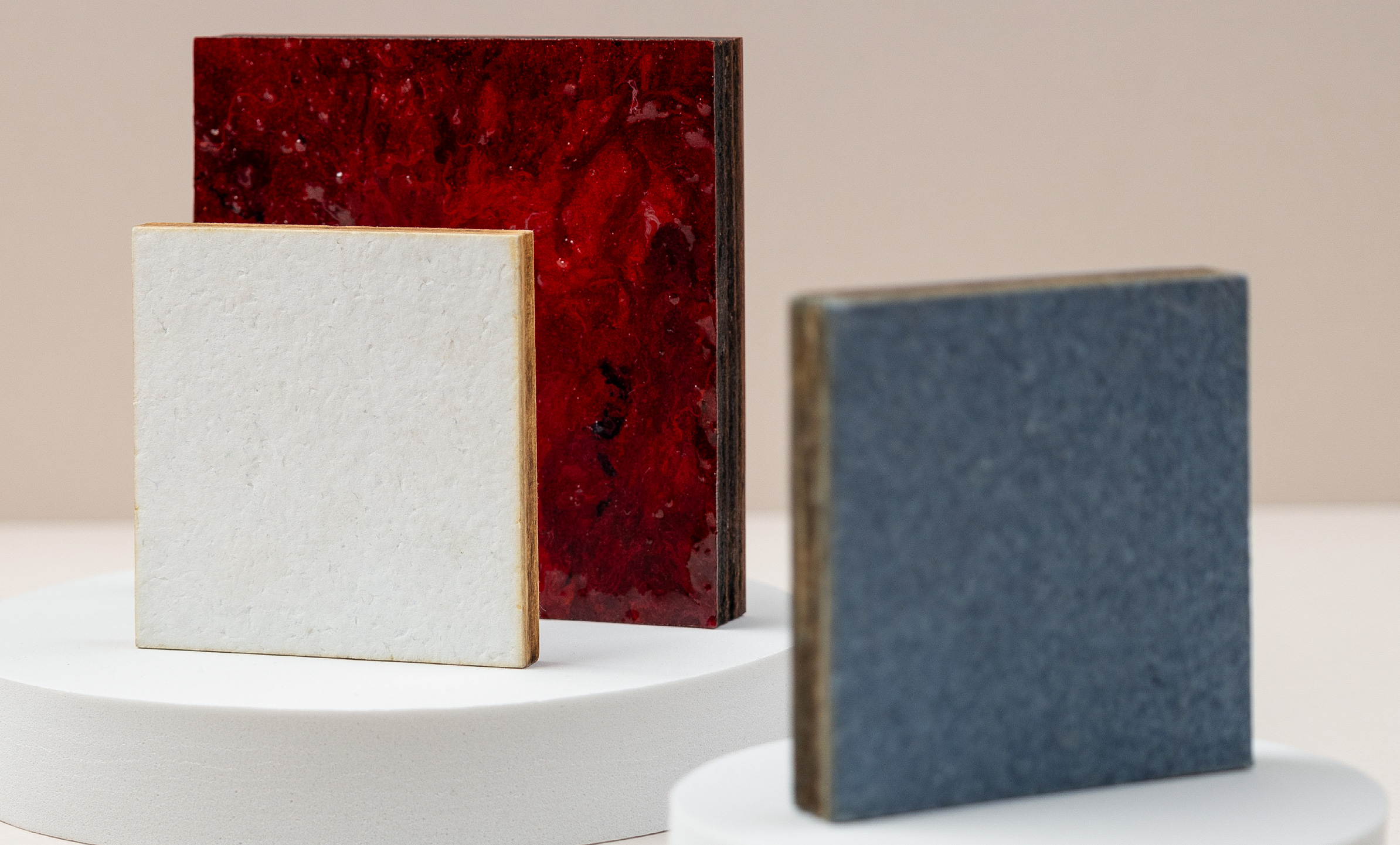

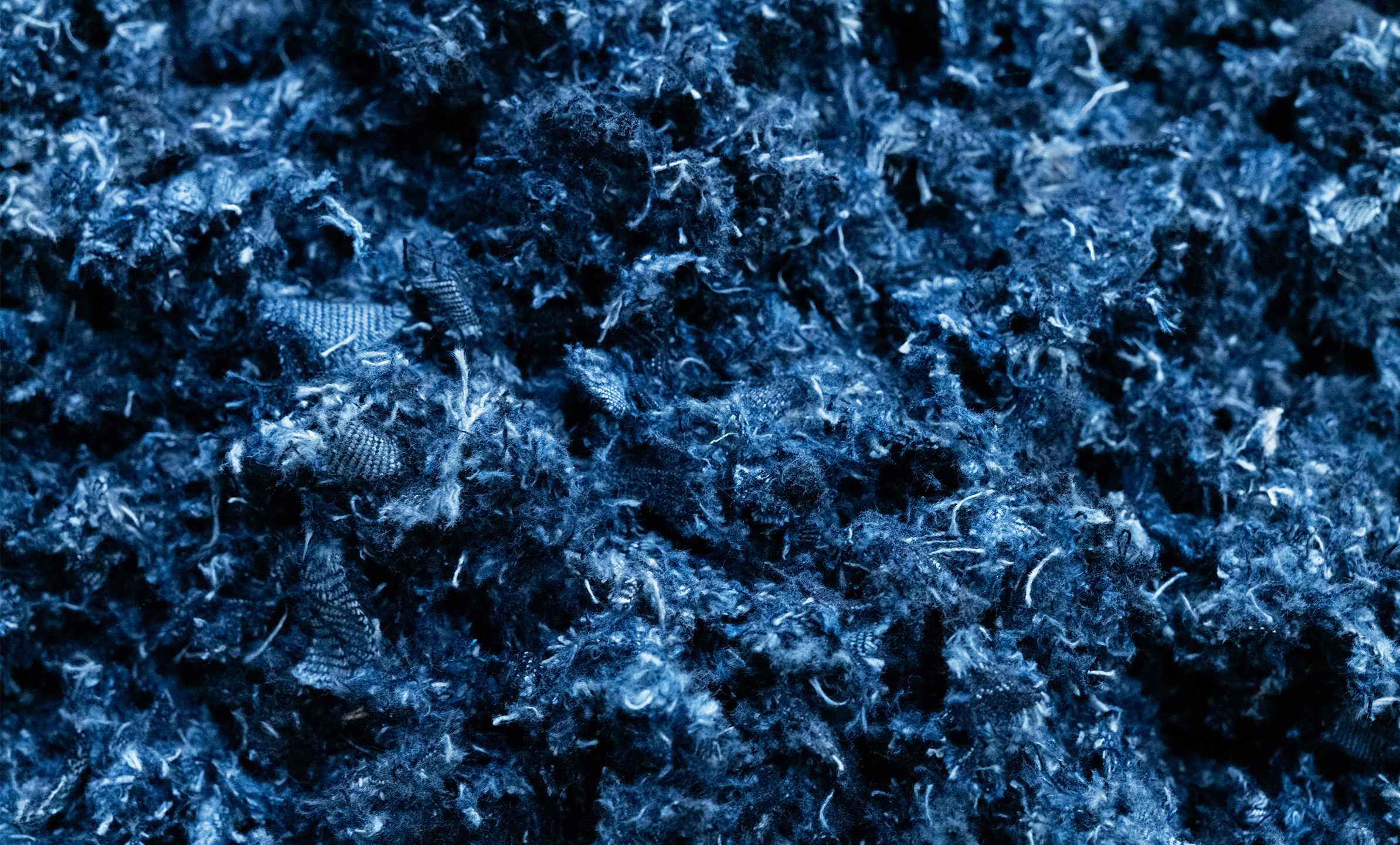

Re-Oxyde is an upcycling project, which calls for the use of inorganic pigments based on iron oxides, obtained by recycling ferrous waste materials from the home appliance industry.

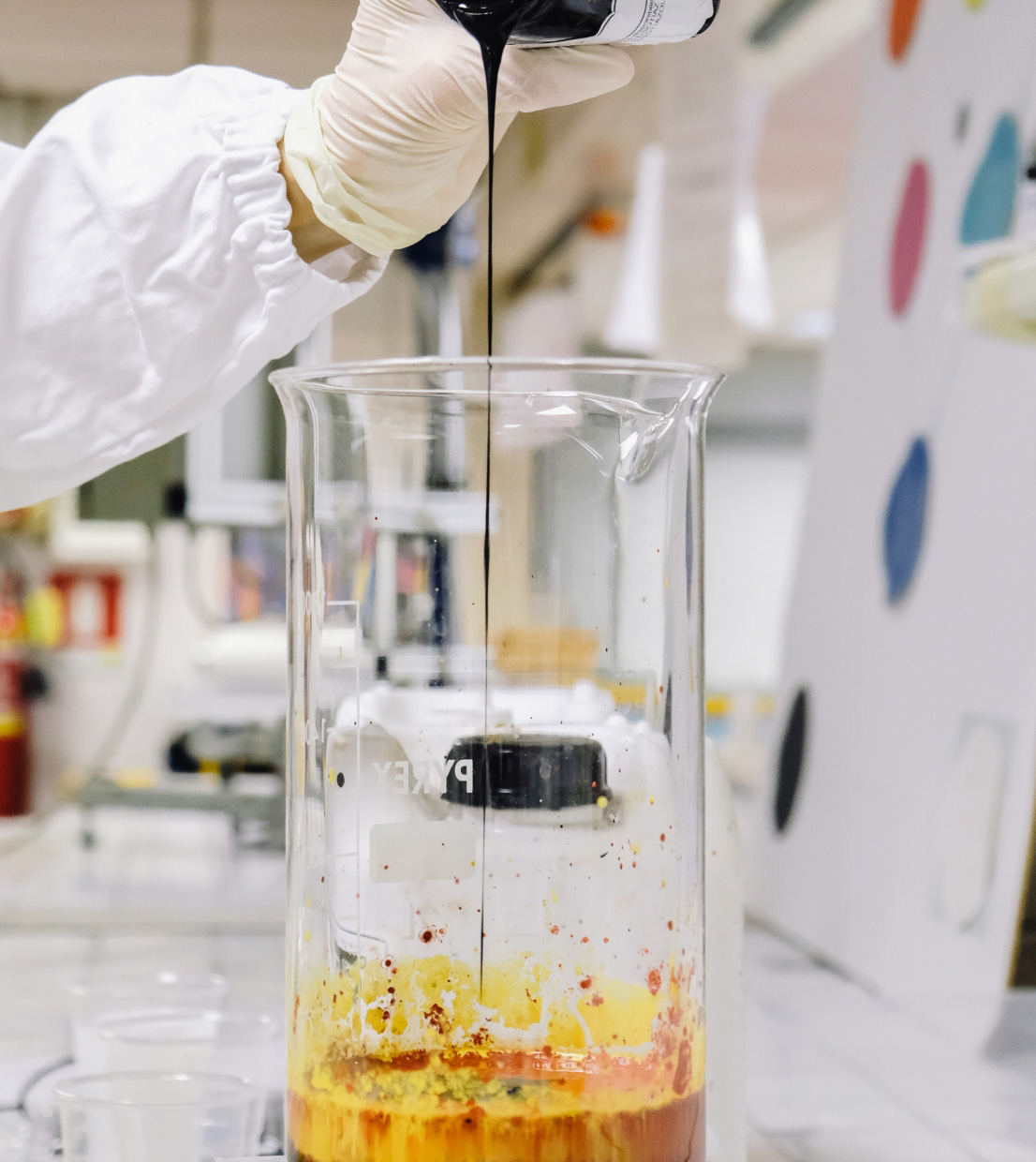

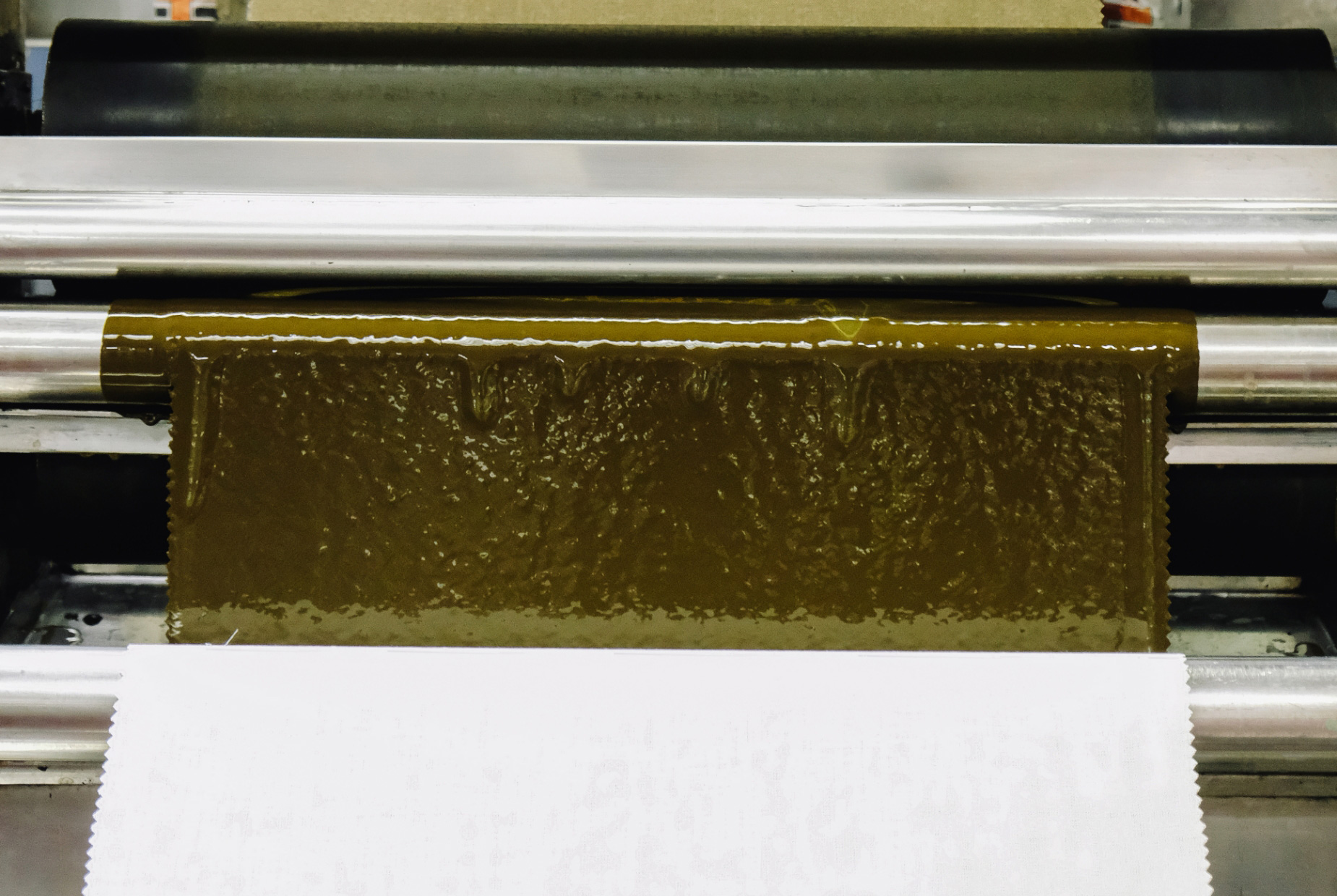

The recycling and oxidation process allows to obtain three different colours.

- Yellow

- Red

- Black

In order to expand the range of colours, ALBINI_next also decided to use the colour blue obtained from a mixture of oxides.

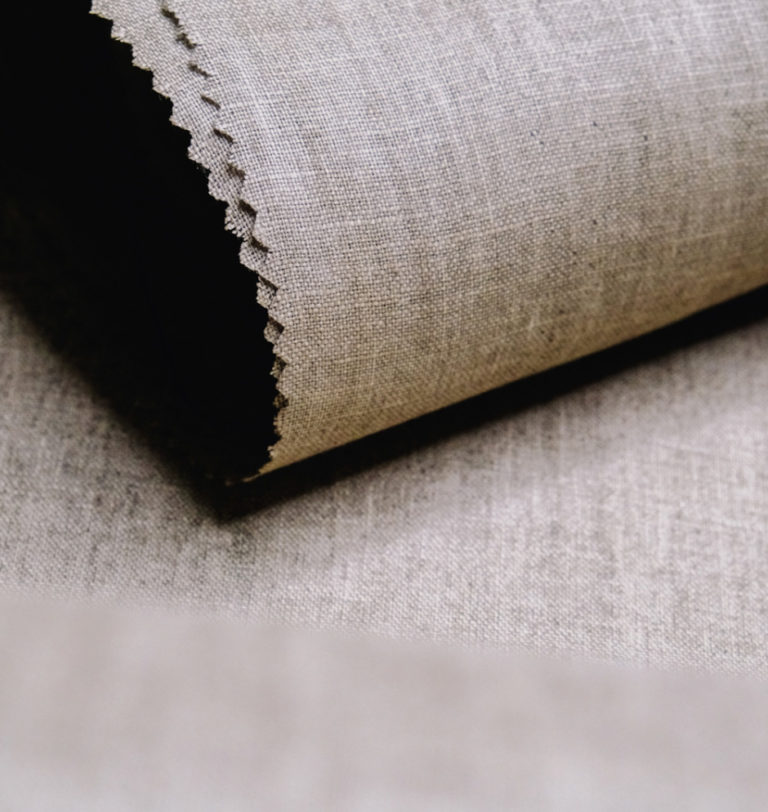

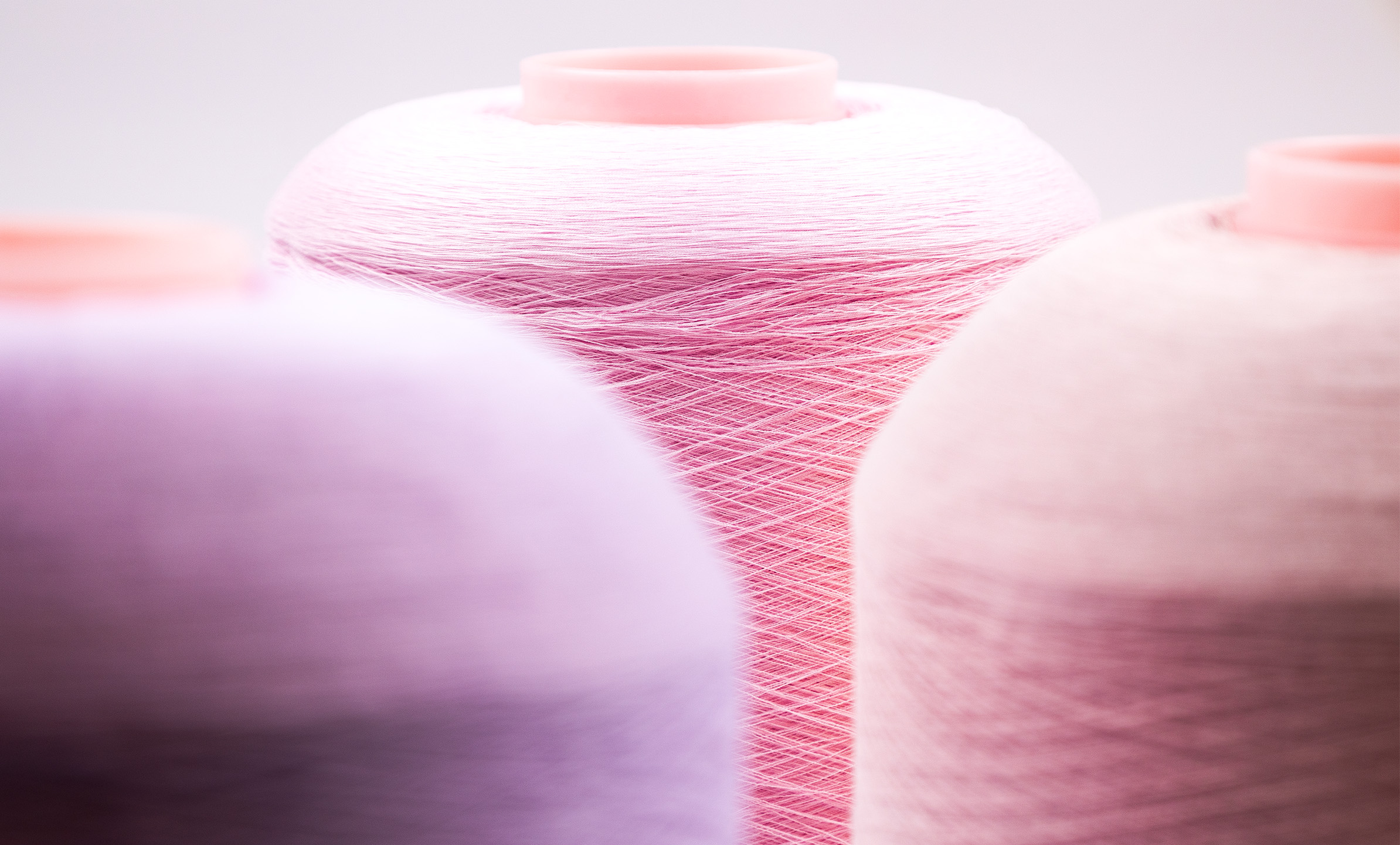

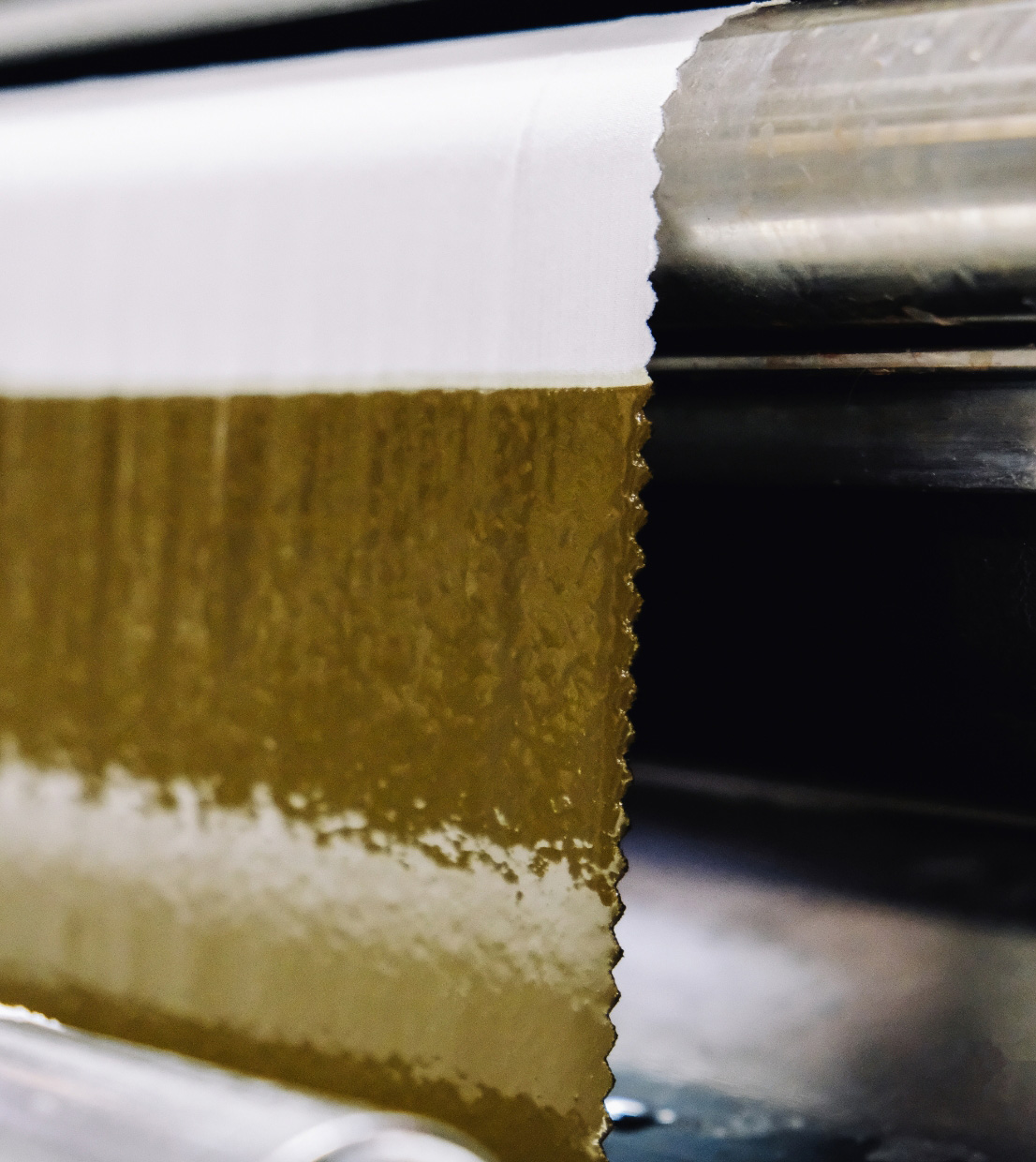

Two dye processes with Re-Oxyde

- Piece-dyeing

- Spray-dyeing on yarn

Re-Oxyde is innovative, sustainable and incredibly effective: the oxides have excellent colour fastness and give the fabric a soft, full hand.