Novus

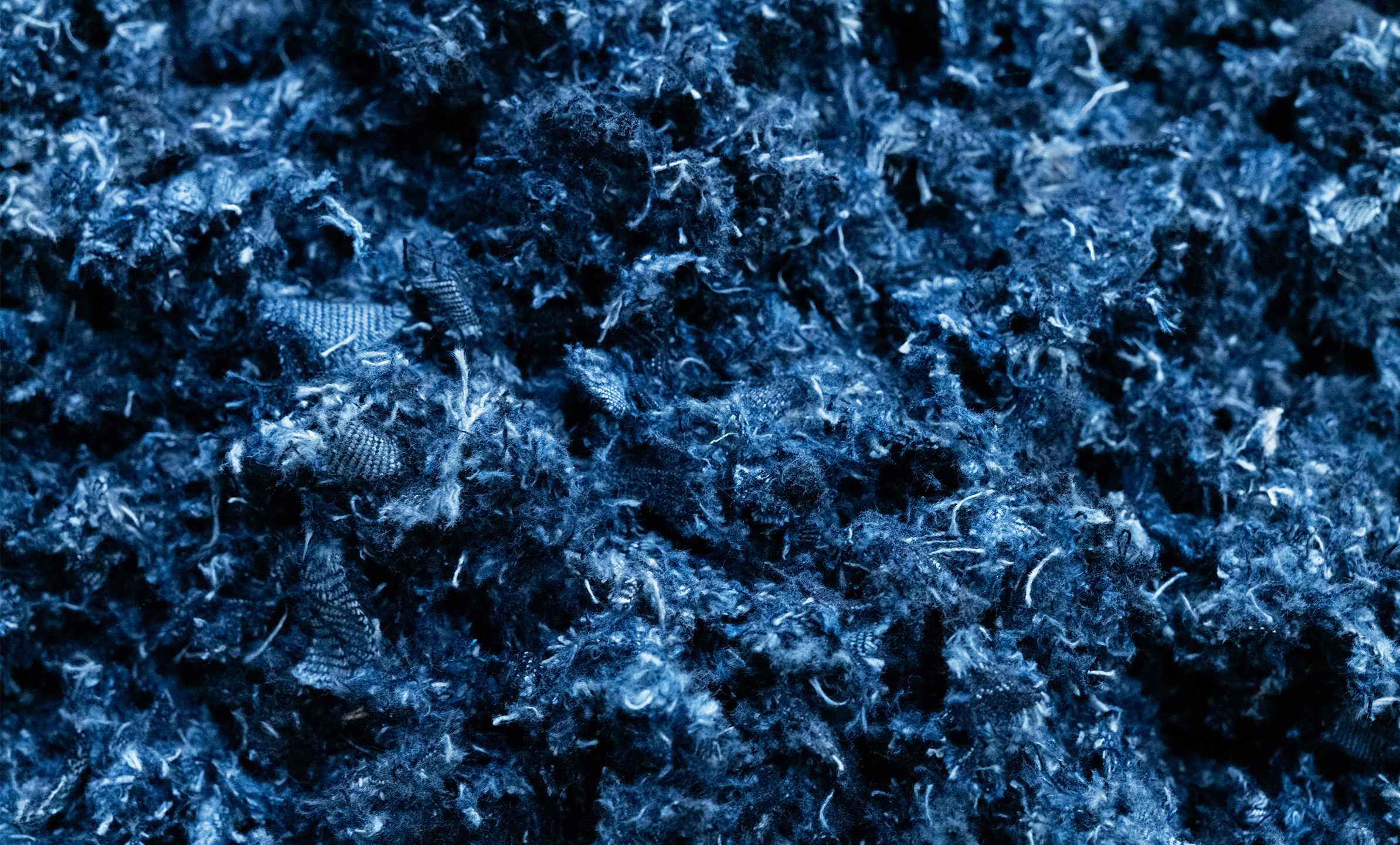

For its Novus project, ALBINI_next collaborated with Renewcell to test the fibre produced from CIRCULOSE® cellulose pulp, obtained from textile scraps.

Worldtextile production is constantly increasing and is expected to grow even more rapidly in the near future. This is because today clothes have become fashion items and as such, have an increasingly shorter product life.

The practice of textile recycling is still uncommon, though it is increasingly being explored and experimented with in its various forms. However, only 1% of scraps today in the European Union is turned into new fabric, while the rest ends up in landfills or incinerators.

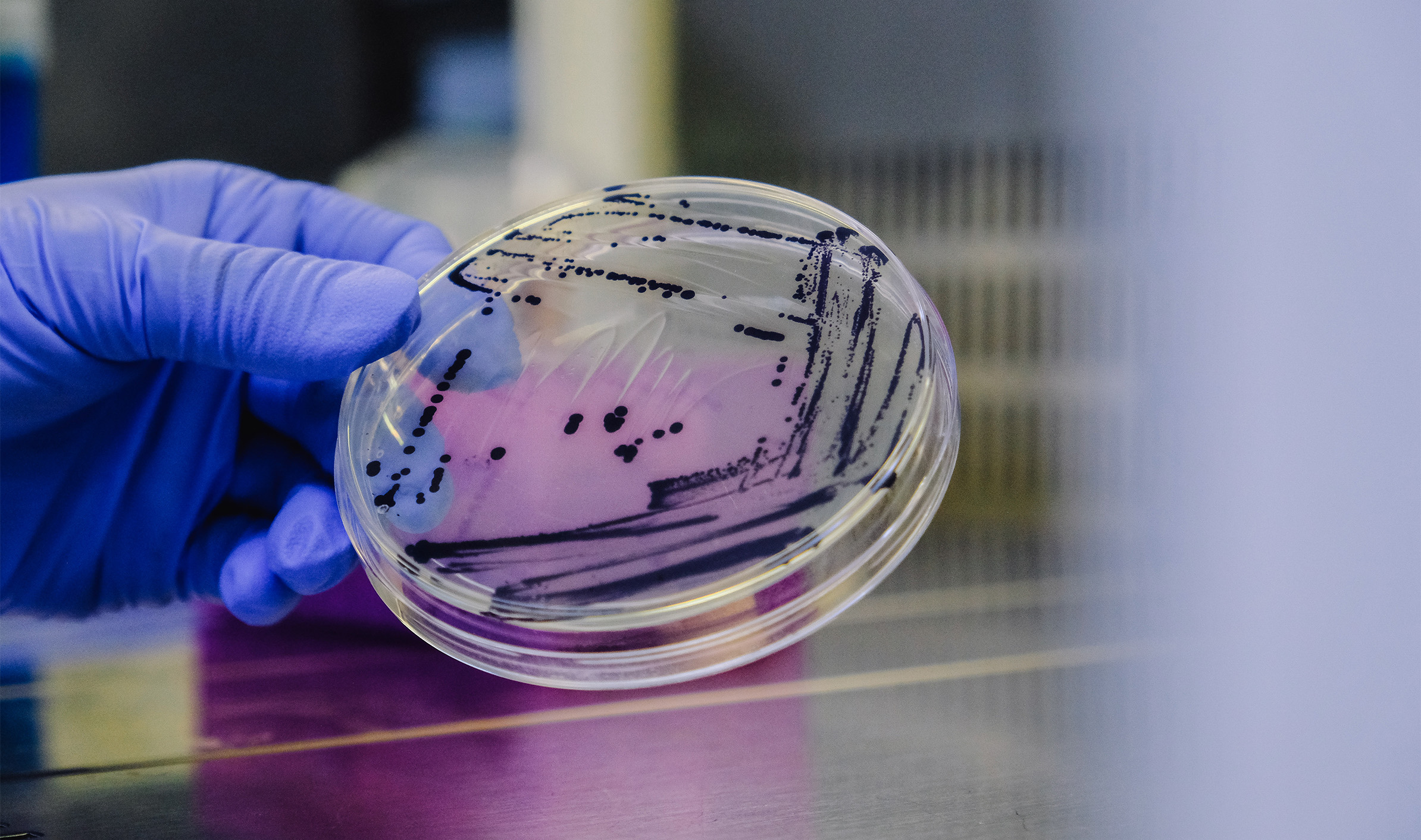

Renewcell, an award-winning textile recycling company based in Sweden, has created a unique and patented process technology based on chemical recycling for the production of CIRCULOSE® pulp, obtained by 100% dissolving of textile scraps. The pulp is then processed into textile fibres of viscose, lyocell, modal, acetate and other virgin-quality biodegradable regenerated fibres. These fibres are then transformed into yarns, woven or knitted, resulting in new high-quality textile products. Unlike other artificial cellulosic fibres, CIRCULOSE® does not require the use of raw materials such as wood, but is made exclusively from textile scraps.

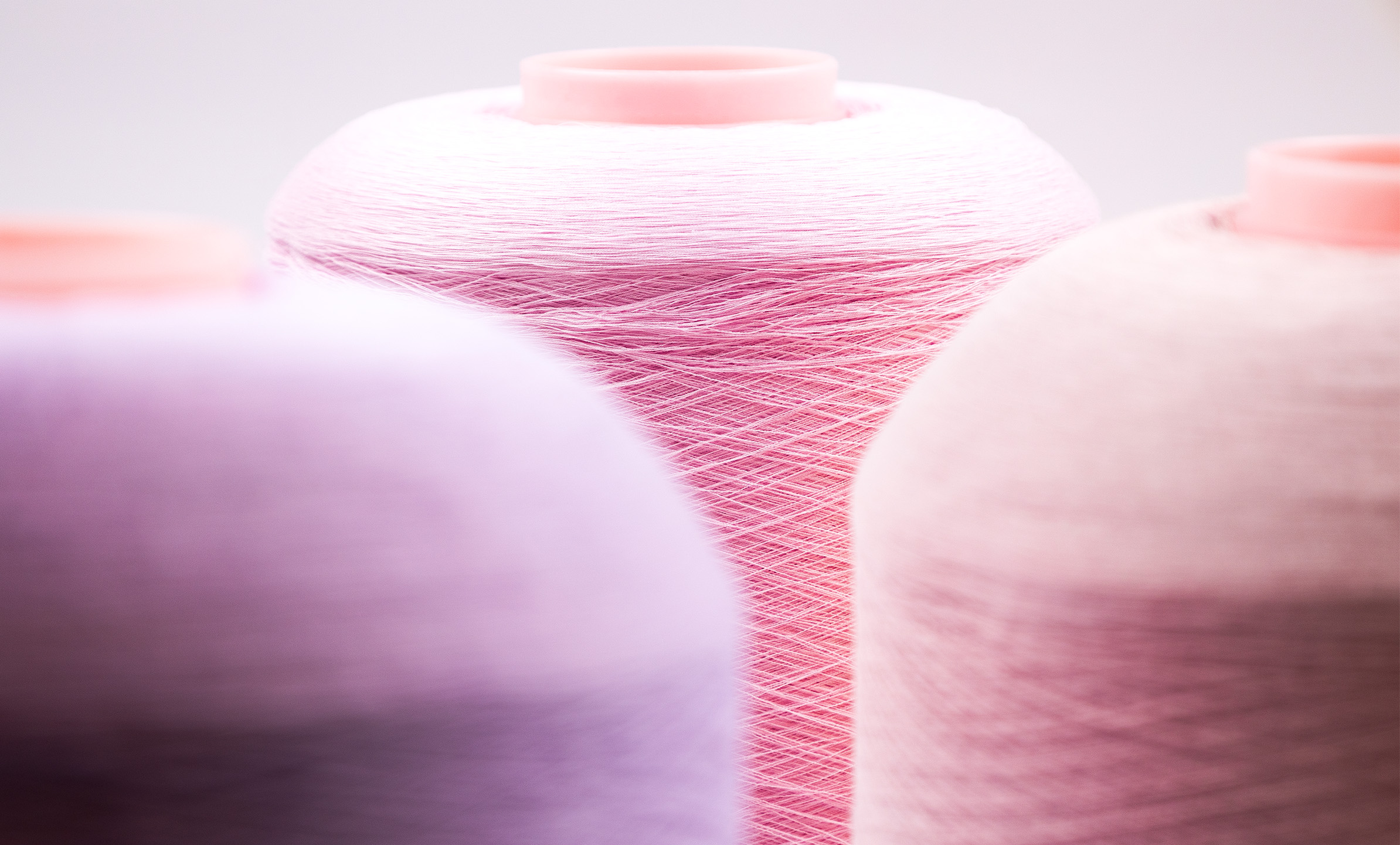

As part of the Novus project, ALBINI_next, after two years of study and with the support of ICA Yarns, has produced several yarns made with the fibre from CIRCULOSE® blended with organic Supima® cotton, linen and wool in thread counts that range from Ne 30/1 to Ne 50/1.

What’s more, thanks to the close cooperation between ALBINI_next and Renewcell, ICA Yarns has joined the "CIRCULOSE® Supplier Network," Renewcell's network of partners characterized by an innovative mindset, an excellent reputation for quality and service, and a commitment to sustainability, and to whom it ensures a steady supply of fiber.