Vertical Indigo

NATURAL INDIGO FROM VERTICAL AGRICULTURE

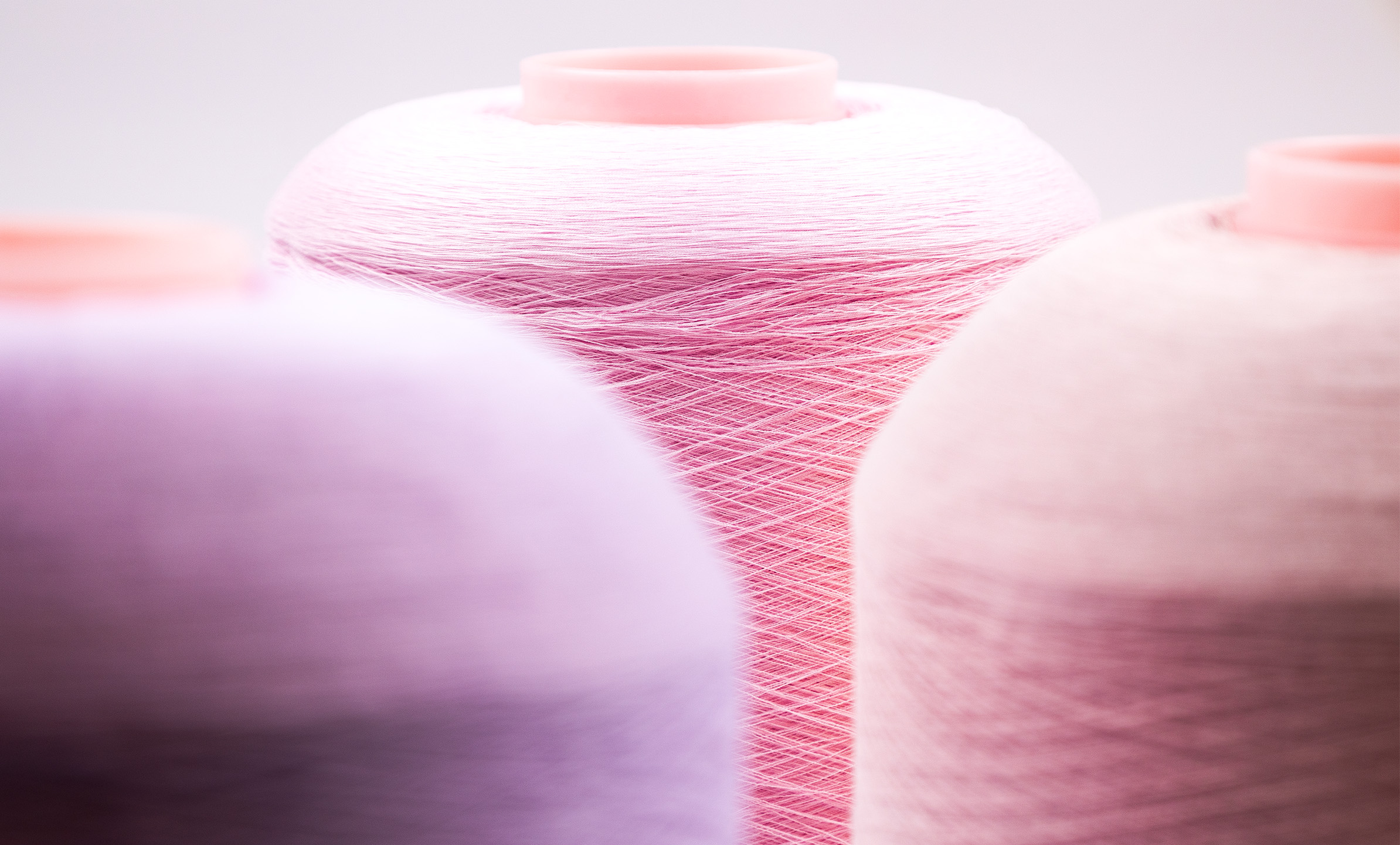

ALBINI_next collaborated with GPM Innovation to study the application of indigo derived from vertical farming in an industrial context.

This pilot project saw the pigment utilised in traditional batch dyeing processes, resulting in a yarn dyed with 100% natural indigo.

GPM Innovation specialises in the implementation of integrated cultivation cycles of botanical species with low environmental impact. The company is also focused on the extraction of pigments and dyes from various plant species, including dye plants, for green industrial applications.

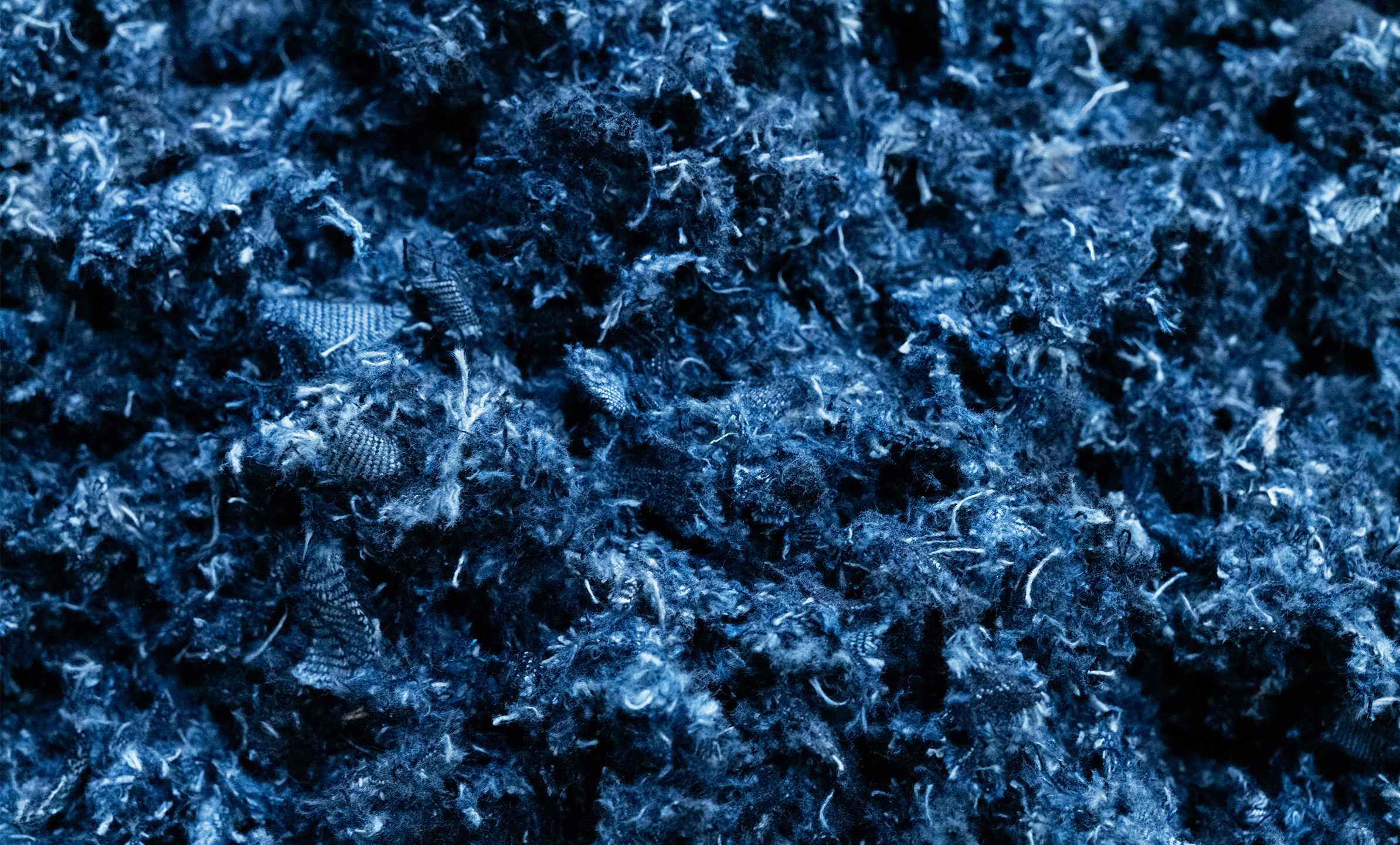

AEROPONIC CULTIVATION

In conjunction with ALBINI_next, the decision was made to cultivate Persicaria Tinctoria in vertical farms inside greenhouses using an aeroponic technique, from which the natural Indigo Blue dye was subsequently extracted.

This cultivation technique does not require the use of soil. Thanks to a support system, it is possible to grow the plantations by feeding them directly on the roots with a spray of water and mineral nutrients. Energy-saving LED lights then provide the necessary illumination.

The advantages of aeroponic farming over traditional systems include: 95% reduction in water consumption; elimination of the use of pesticides and herbicides; reduced land usage; increased productivity; simulation of any weather condition at any time of the year.

INDIGO PRODUCTION

The production of indigo begins with the harvesting and cleaning of the seeds of Persicaria Tinctoria plants that have flowered and ripened.

Subsequent germination takes place in the controlled environment of the germinator inside the vertical farm.

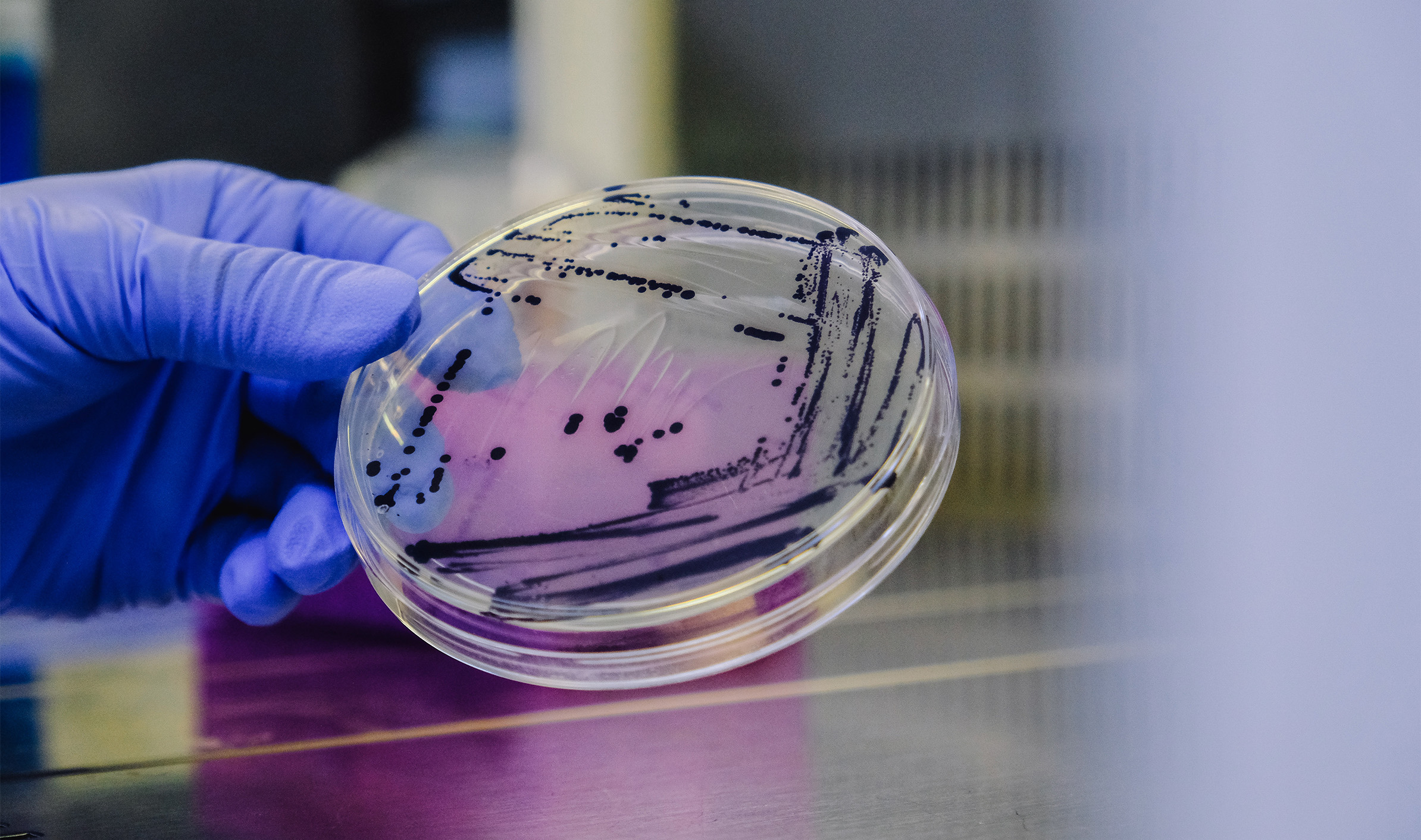

Once the plants have reached proper levels of growth, they are cut and macerated to extract the indigo.

Subsequently come the steps for preparing the pigment and drying to produce ready-to-use indigo powder.

A TOTALLY BIO-BASED FORMULA

Again in collaboration with GPM Innovation, ALBINI_next’s research also focused on the development of the dye application formula and the use of bio-based auxiliary products, which contribute to the sustainability of the entire dyeing process.