Weav3d

A STUDY OF POLYMERIC COMPOSITE MATERIALS FOR 3D PRINTING APPLICATION

Albini Group is continuously committed to reducing and recycling the textile waste generated during the various manufacturing phases, which it aims to reuse and recycle in a circular economy perspective.

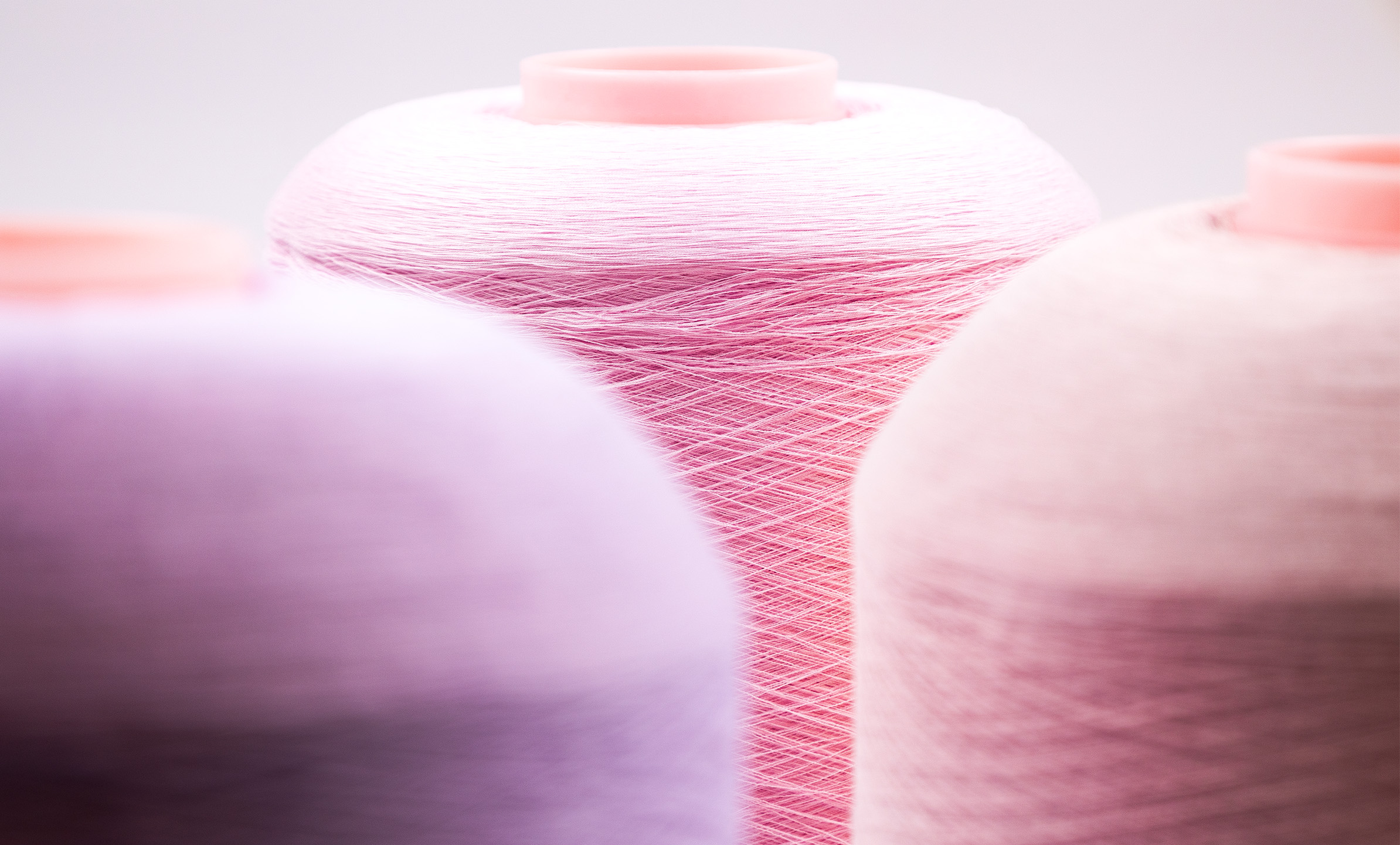

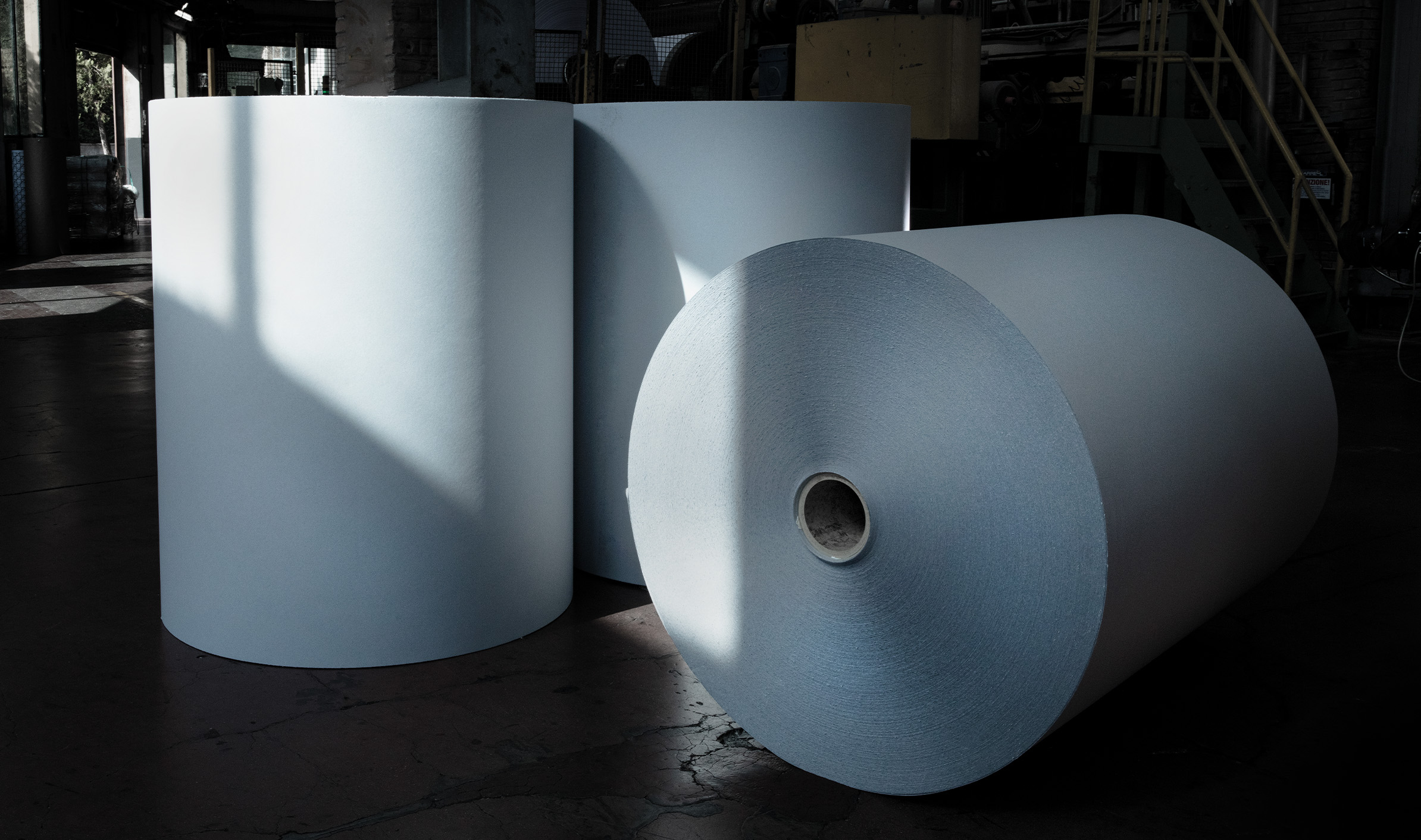

With the Weav3d project, ALBINI_next has launched an exploration of biopolymer composite materials as a solution for recycling textile fibres, creating unique blends of bio-based and/or recyclable polymers combined with textile fibre of plant origin.

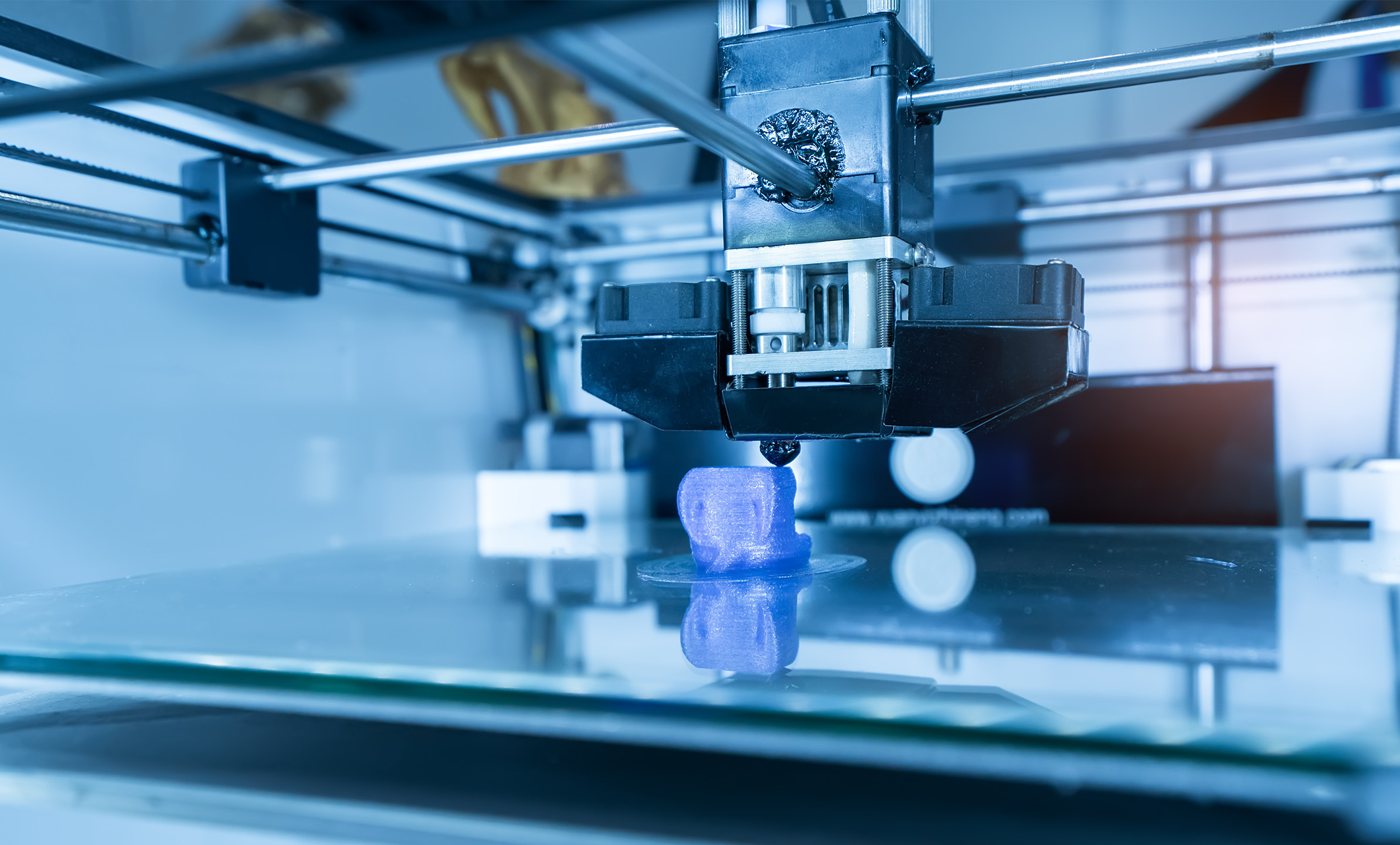

These new materials have a wide range of applications, including 3D printing, and can give rise to innovative products.

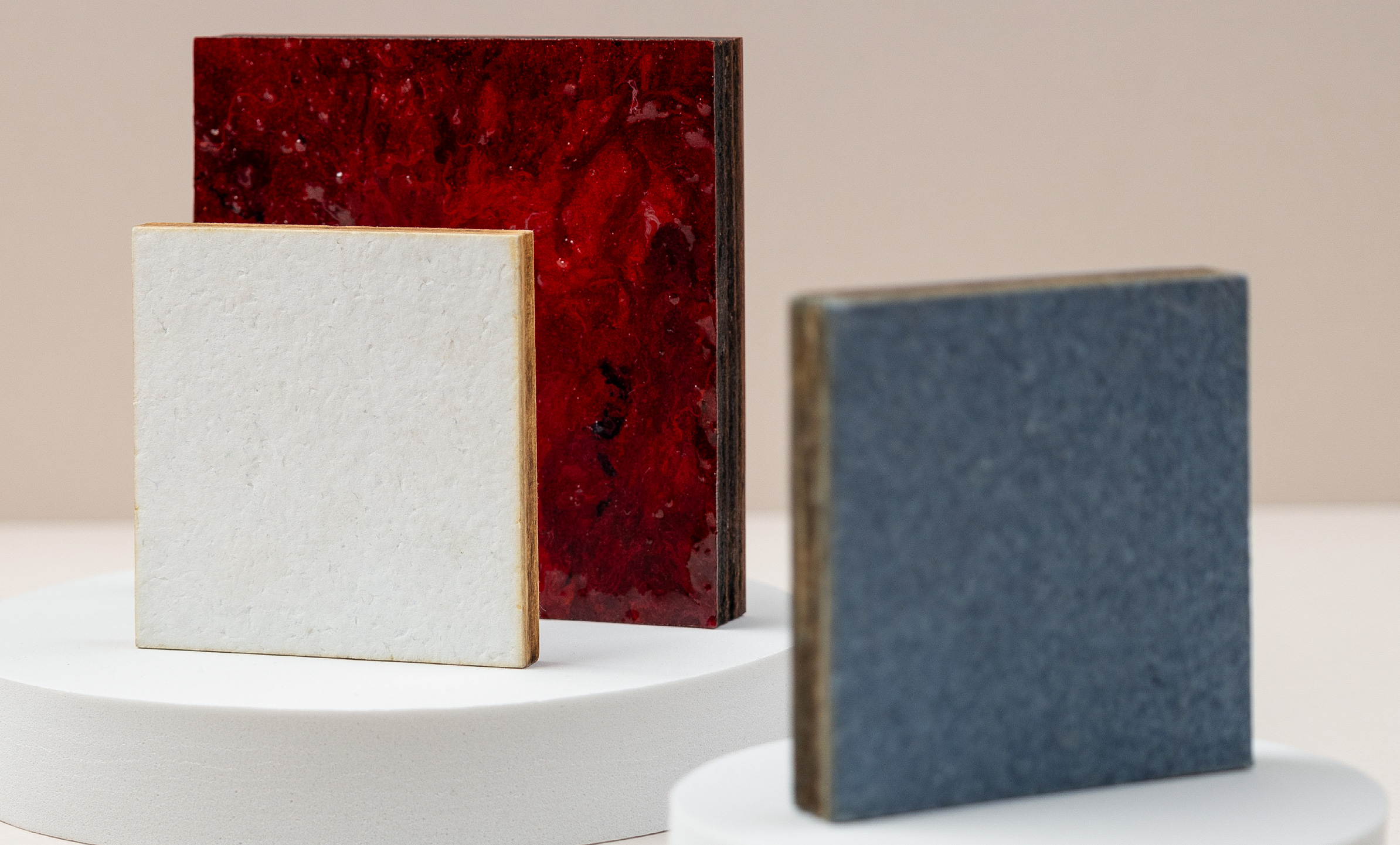

As of today, ALBINI_next has developed two polymers blended with cotton fibre in an ecodesign perspective. The first polymer was chosen for its flexibility and recyclability, while the second is a stiff, bio-based and recyclable polymer.

It has been proven that adding textile fibres strengthens the polymeric material, making it stiffer, as well as giving it a unique and special appearance due to the plant nature of the fibres. What’s more, the finished product’s colour is derived from the original dyeing of the selected textile scraps, thus preventing chemical pigments from being used.

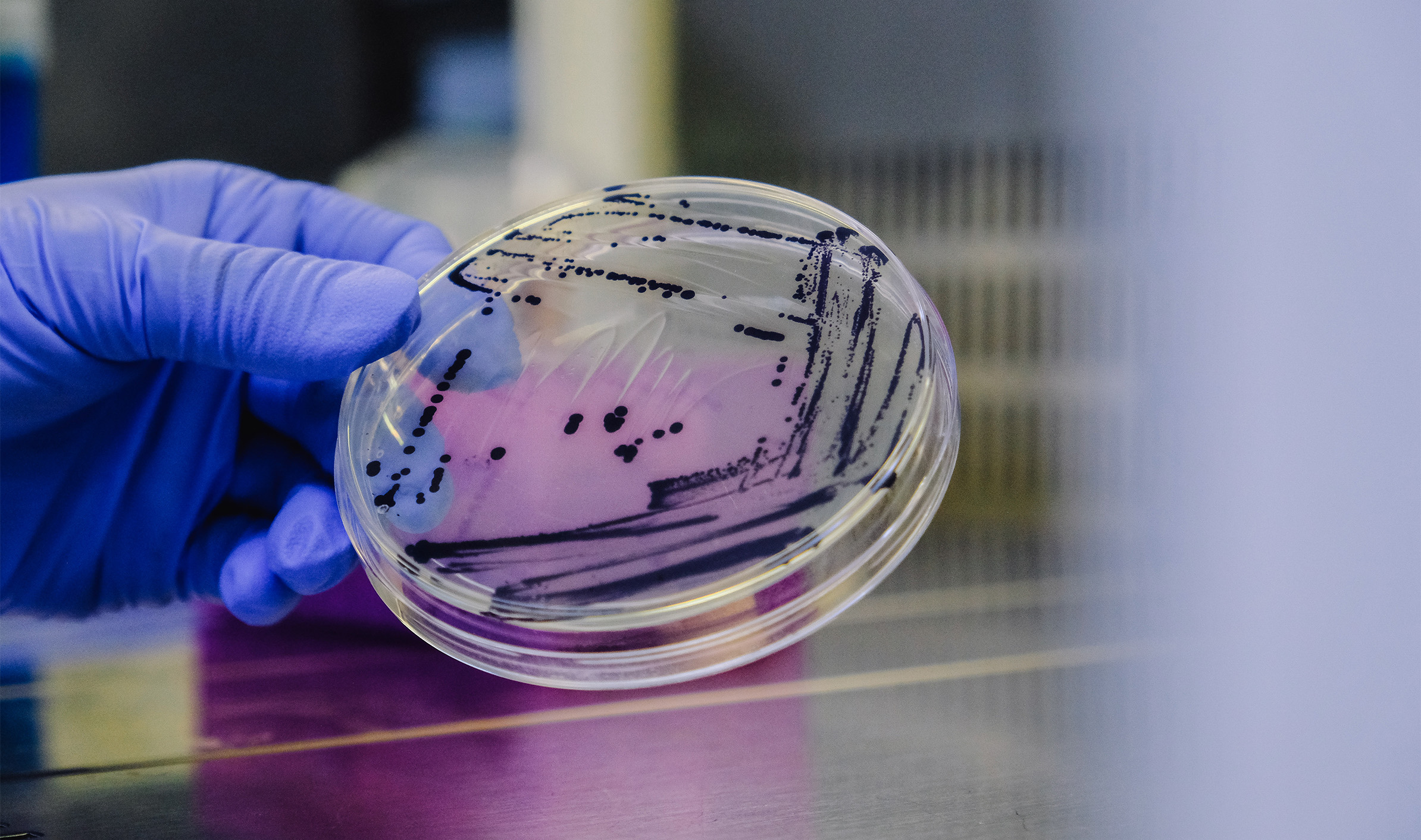

To bring the Weav3d project to life, ALBINI_next collaborated with several partners. Mixcycling, a young company with long-standing experience in the bioplastics field, has provided know-how in order to develop and characterise the blends generated by recycling textile fibres.

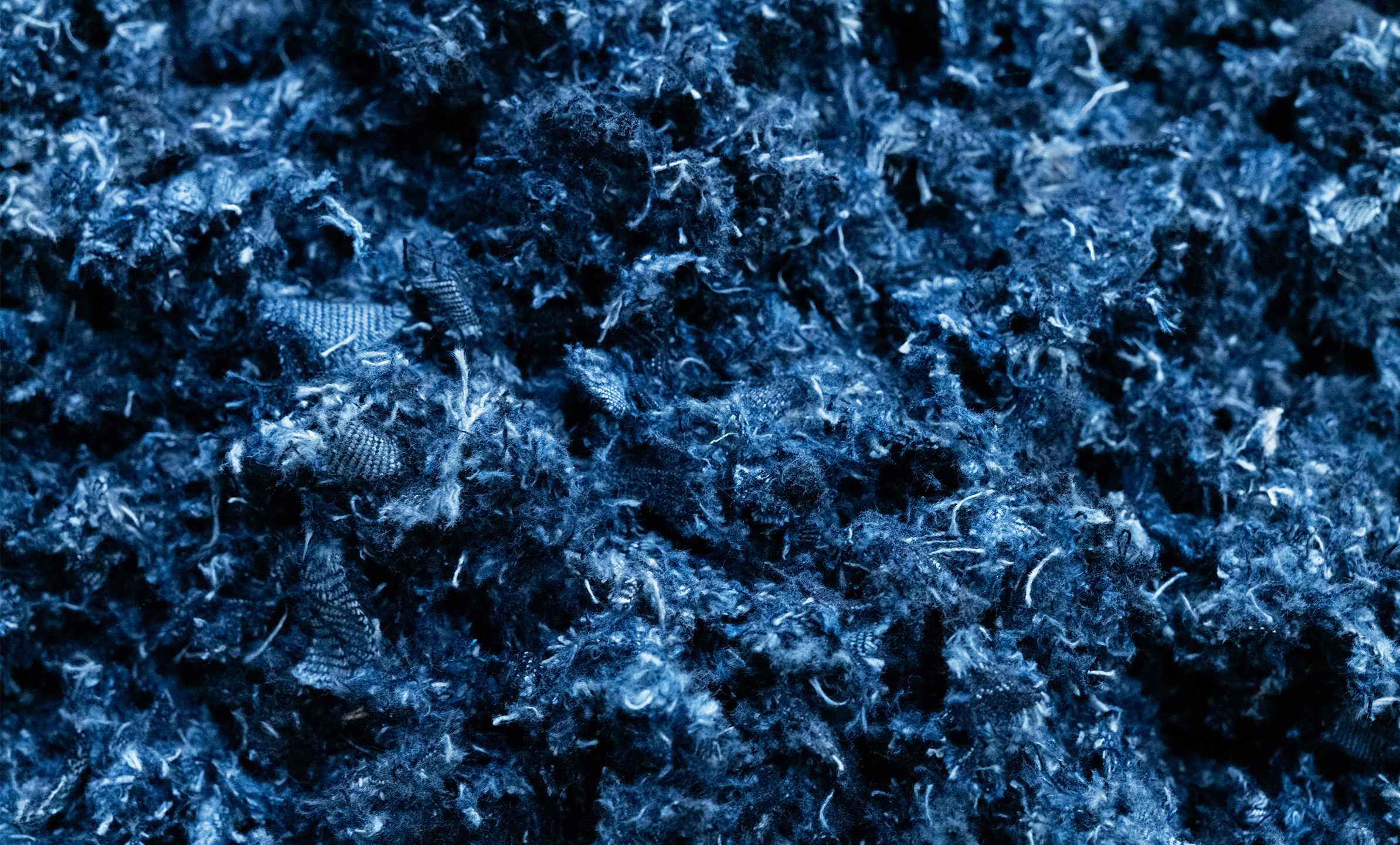

Nazena, an Italian start-up company devoted to upcycling textile fibres, used its technologies for the preliminary stage of transforming textile scraps into small fibres, making them suitable for use in the subsequent blending stages.

Finally, PSCT Digital Lab employed its creativity and expertise in using digital systems to design objects and test new materials with additive manufacturing technologies.

But ALBINI_next’s research and active collaboration with its partners doesn’t end here. The aim is indeed to continue to develop other blends to repurpose and give new value to textile scraps.