Black Wood

A NEW SUSTAINABLE BLACK FROM WOOD WASTE

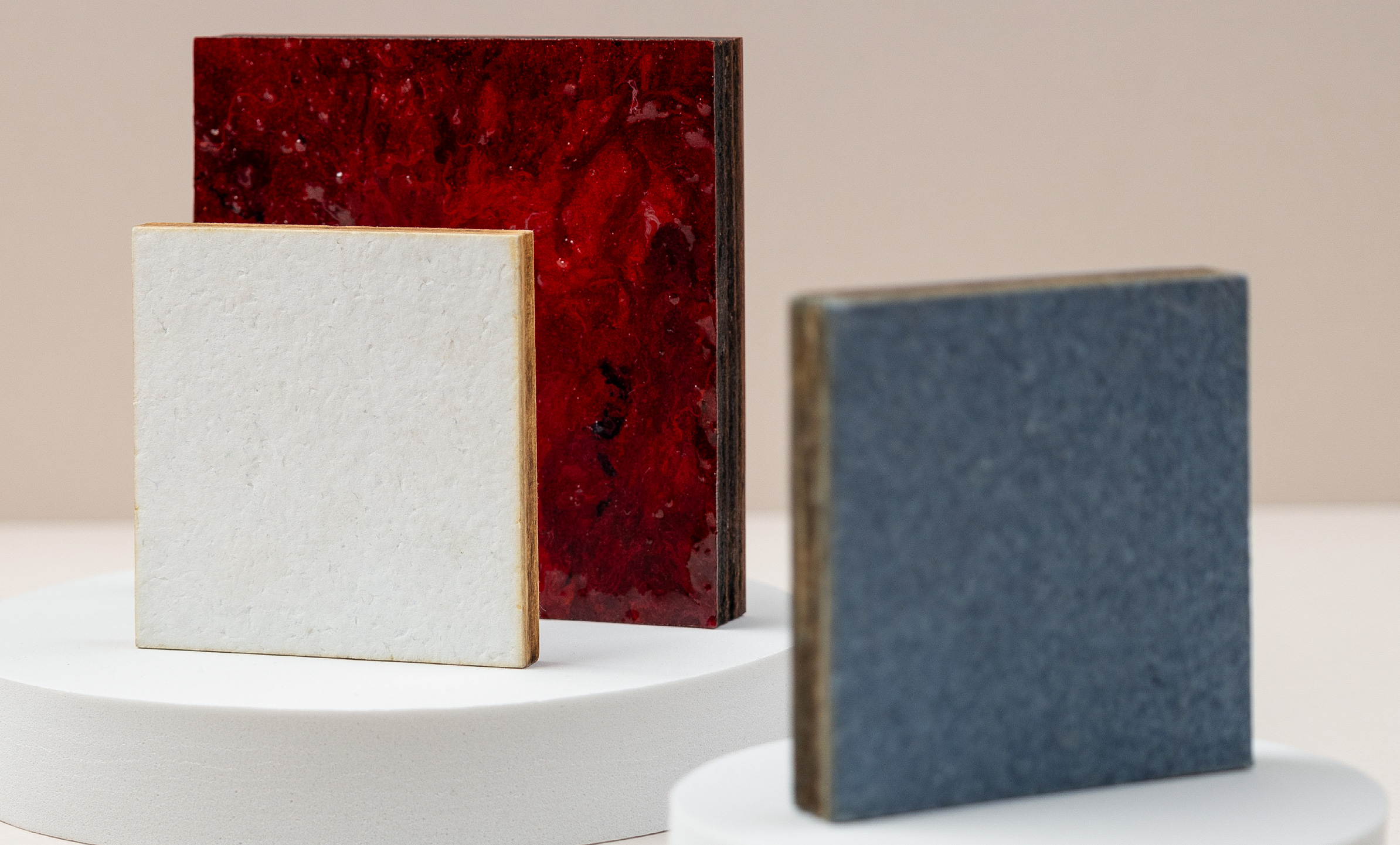

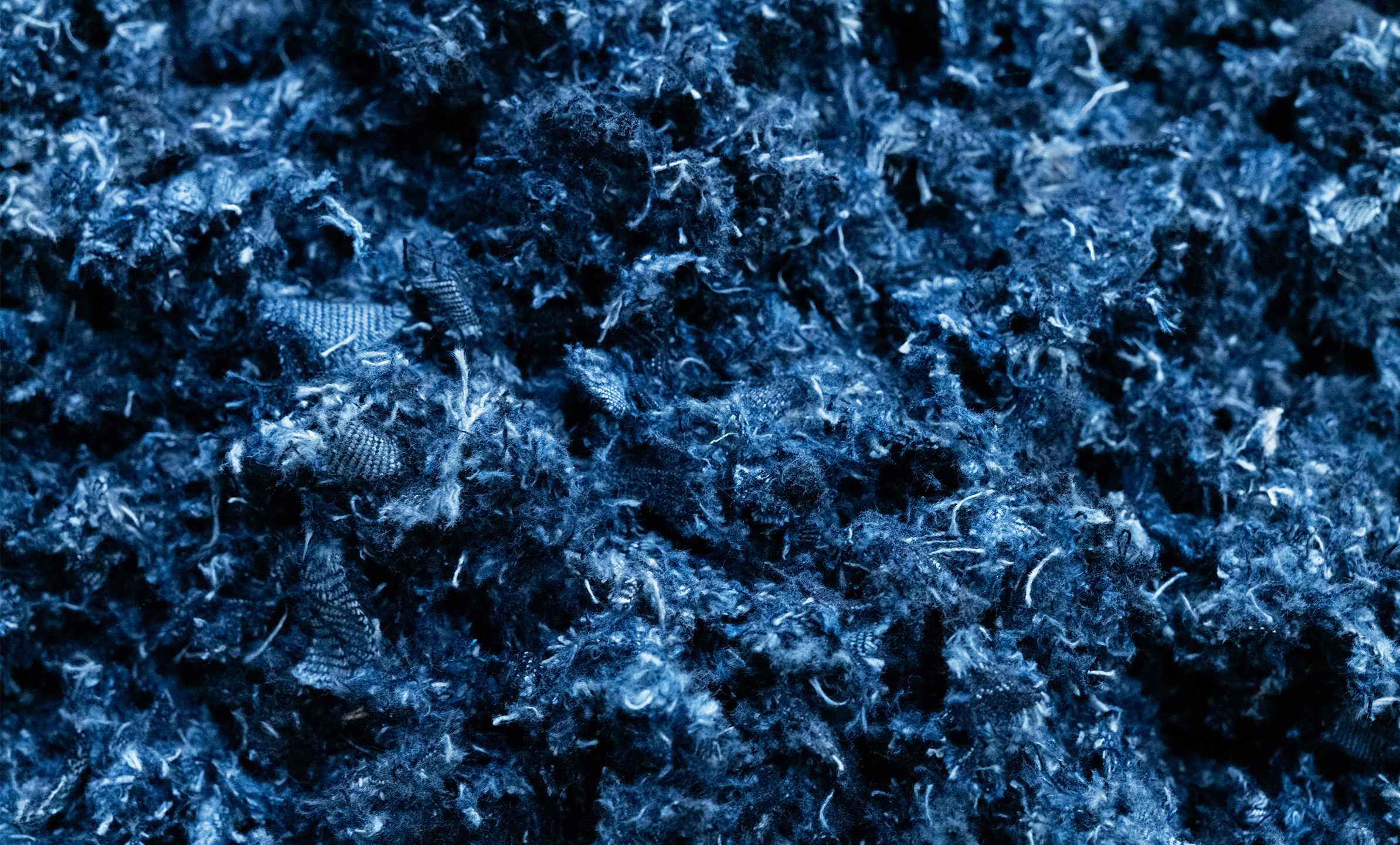

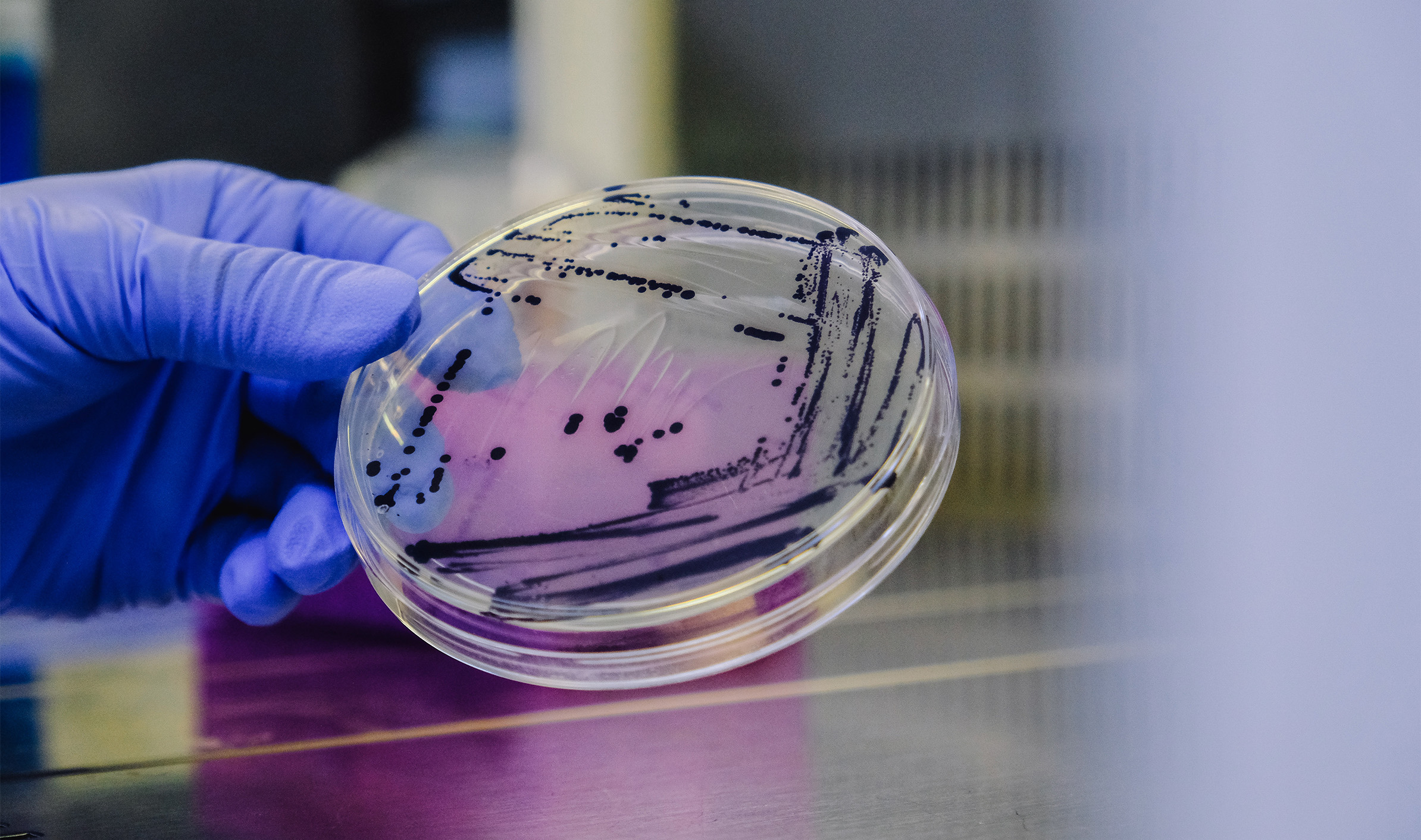

For its “Black Wood” project, ALBINI_next has introduced a new sustainable solution to the Albini Group brands’ collections: the cleanest black pigment on Earth made from wood waste, BioBlack TX.

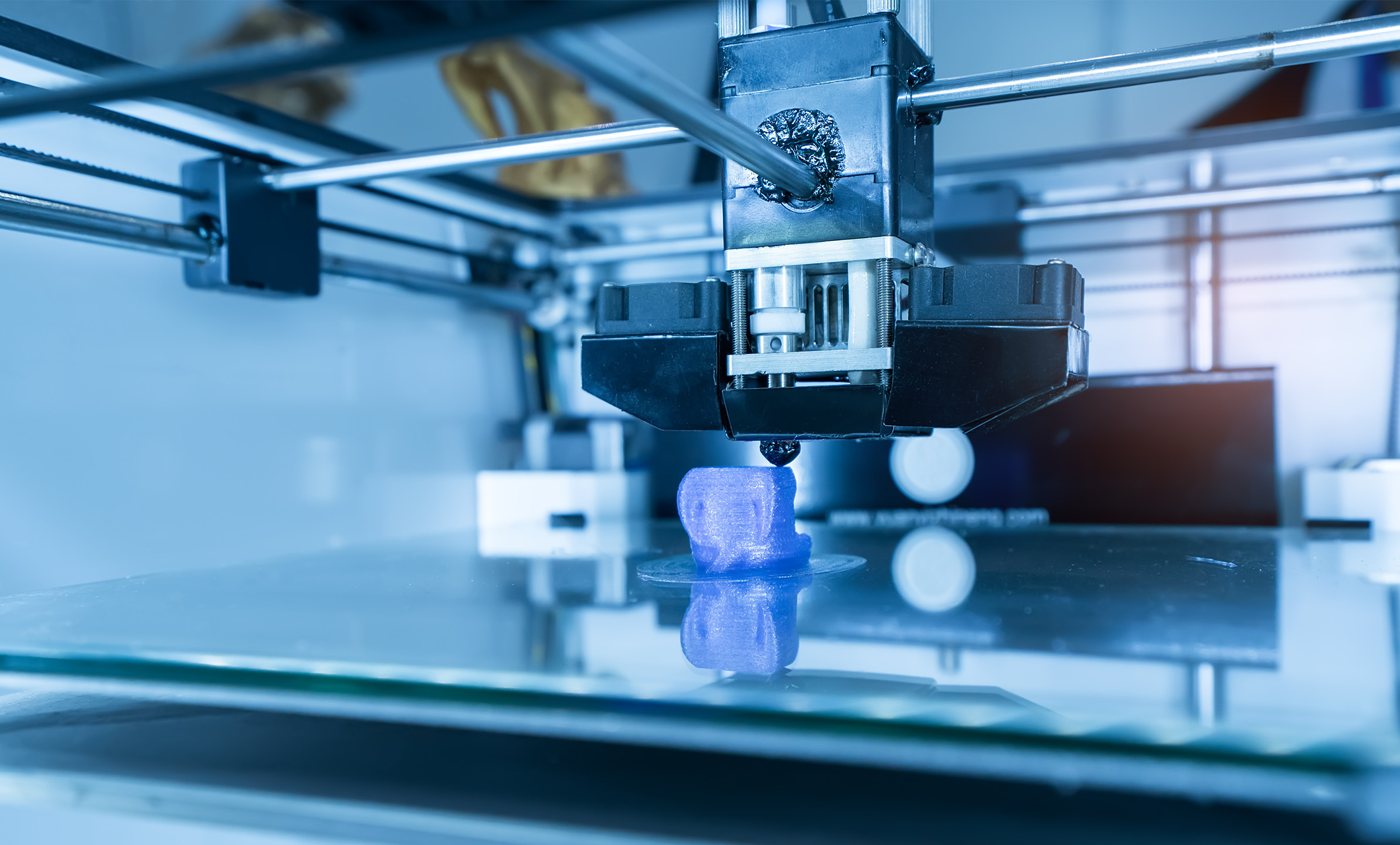

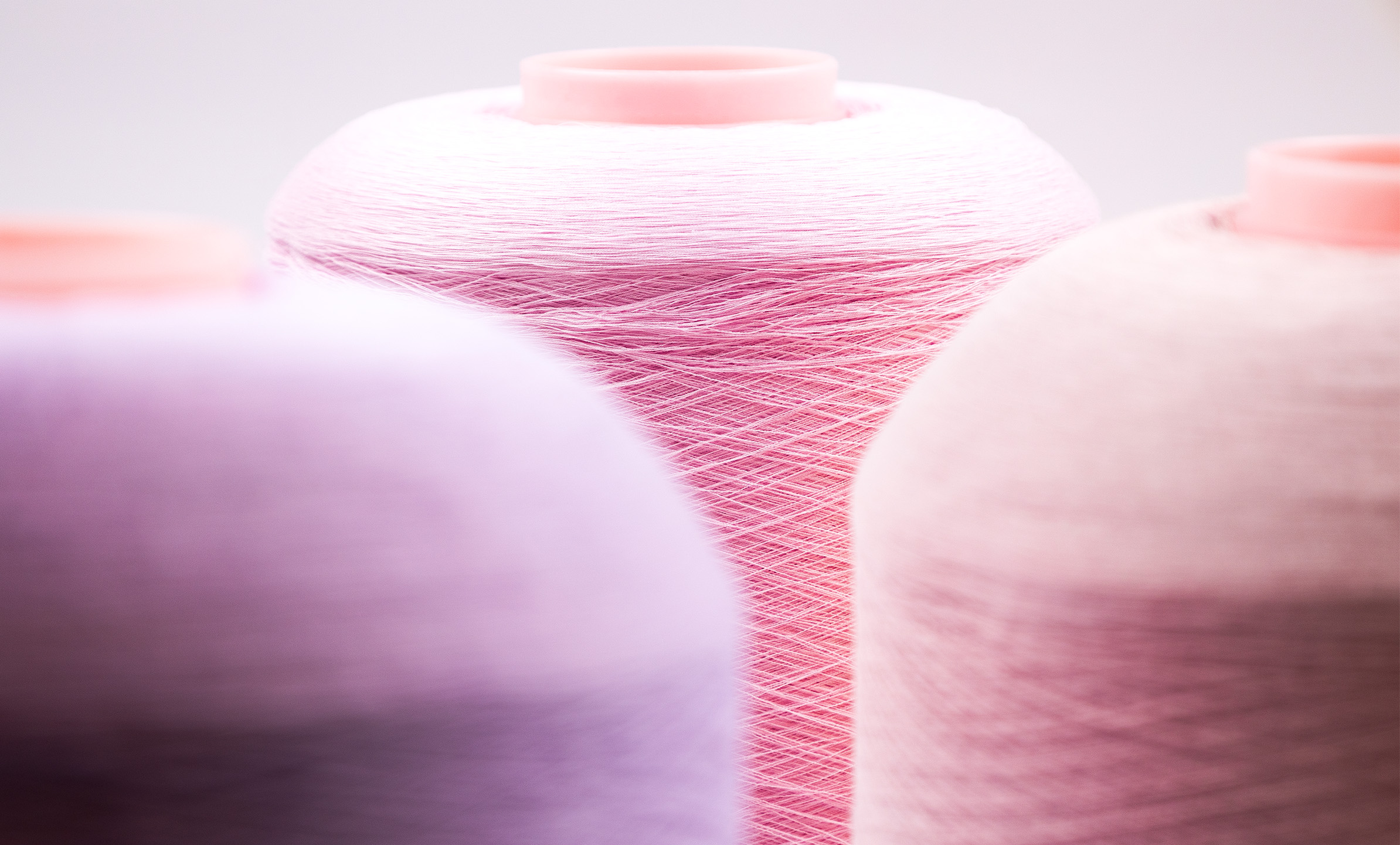

With this innovative machine, yarn is not immersed in a bath, but sprayed, thus saving considerable amounts of water compared to classical dyeing systems. In fact, this technique uses only 1 litre of water per 1 kg of yarn (thereby explaining its ‘ONE to ONE’ name), and is an excellent sustainable solution.

In collaboration with Stamperia Olonia, ALBINI_next has also applied this pigment with traditional textile printing, thus demonstrating its extraordinary versatility.