Exteria

DYES MADE FROM ENGINEERED BACTERIA

Albini Group and Colorifix collaborate on “Exteria – Dyes from bacteria”, a pioneering project that turns the idea of sustainable fashion into reality. The project is aimed at the transition from synthetic dyes to colours coming from engineered microorganisms.

ALBINI_next have joined forces with Colorifix, a biotechnology company, for a pioneering project that responds to a common goal: finding new sustainable technologies and materials for the fashion industry.

The “Exteria” pilot project, sponsored by the Albini Group and supported by the Kering’s Material Innovation Lab (MIL), gives life to dyed fabrics thanks to the use of engineered bacteria through synthetic biology practices, a scientific discipline straddling engineering and biology to build artificial biological systems.

ALBINI_next and Colorifix, uniting their know-how, have validated the dyeing of yarns with colours produced by engineered bacteria on an industrial scale and with conventional machinery, through a technology that saves water, energy and does not involve the use of harmful chemicals.

THE COLOR CREATION PROCESS

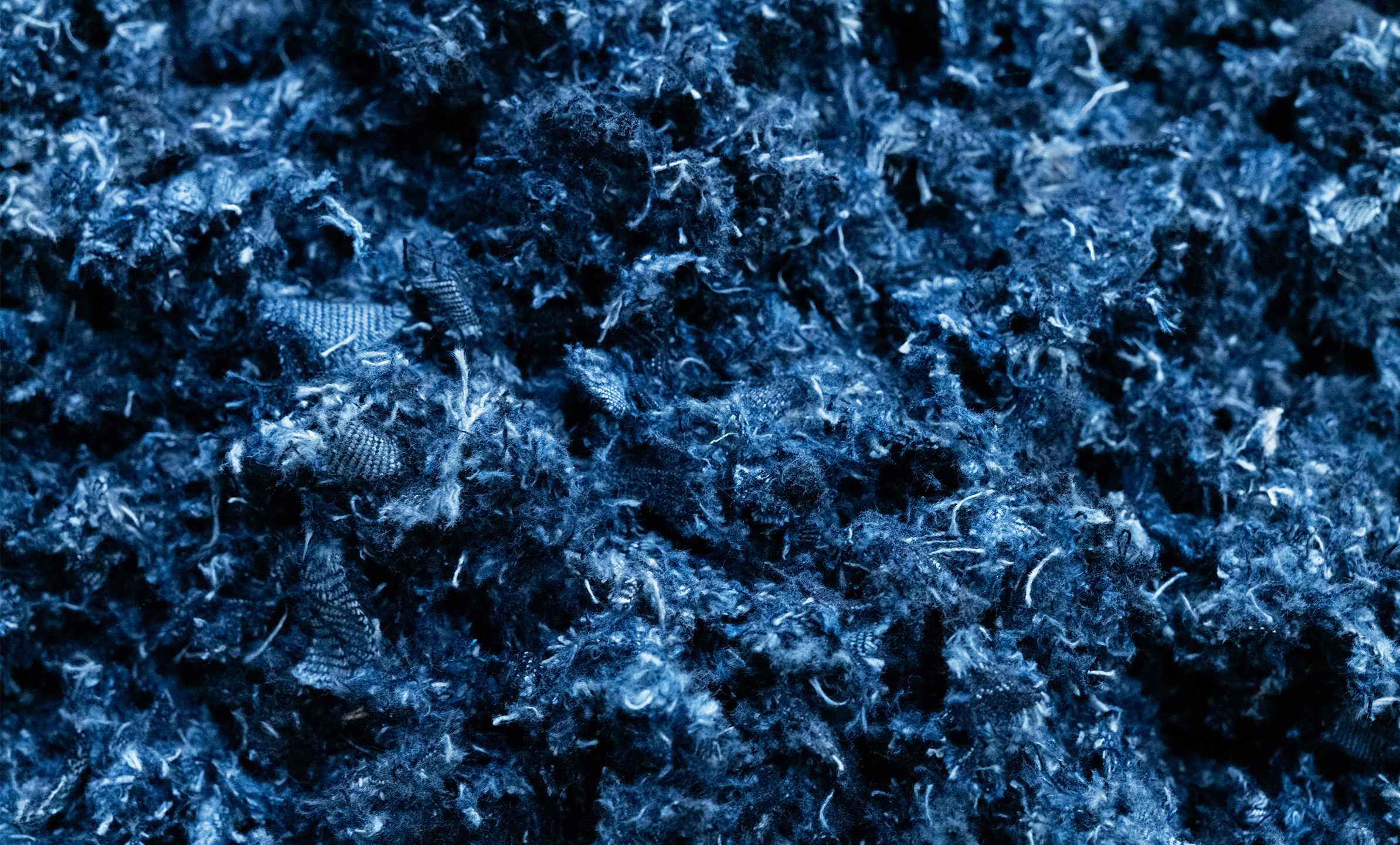

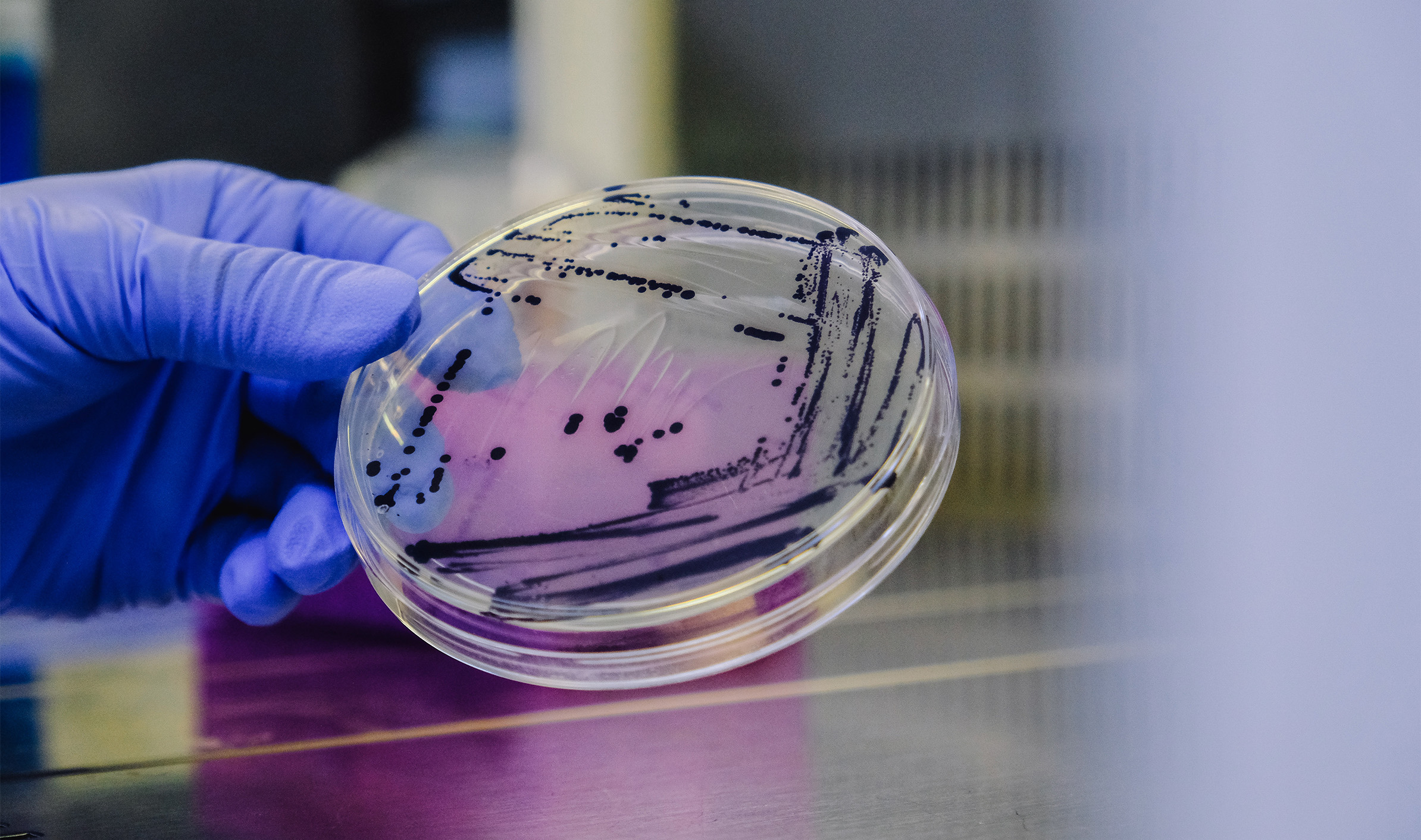

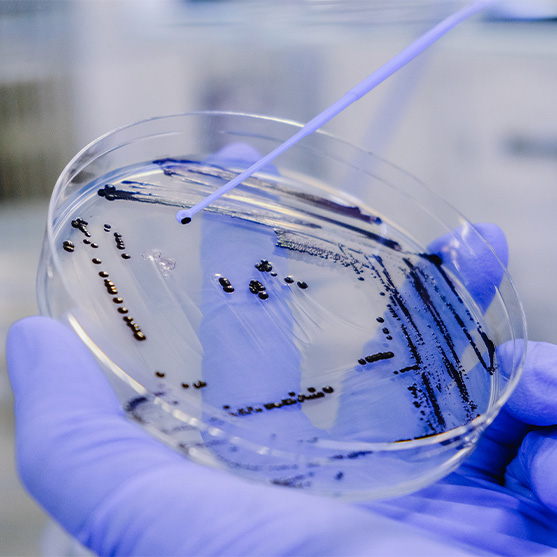

The first step in the process is to find a colour created by an organism, whether it be an animal, plant, insect or microbe. Through searching metabolic, protein and DNA databases, Colorifix technology identifies the exact genes that lead to pigment production, all without harming any living organism. Synthesised gene DNA is inserted into a microorganism that can then produce the pigment just as it occurs in nature.

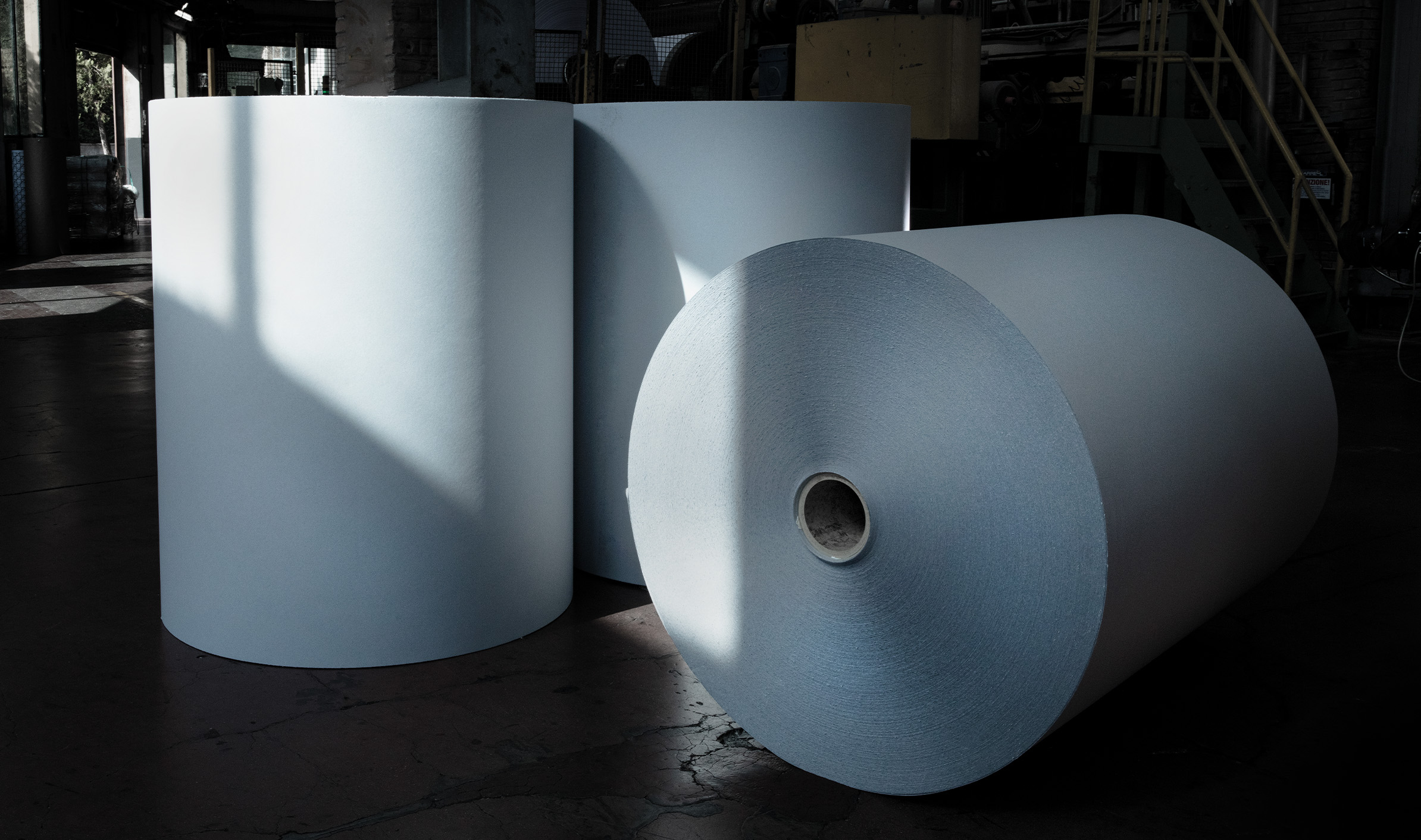

In order to treat these engineered microorganisms, ALBINI_next has equipped itself with a fermenter and a bio-lab, installed at the Albini Group plant in Albino (Italy). These engineered microorganisms grow in the fermenter, nourishing themselves on renewable raw materials such as simple sugars, salt and plant by-products.

Once the peak of pigment production has been reached, the dye liquid in the fermenter is transferred to standard dyeing machines together with the yarn. This liquid, called ‘bacterial broth’, entirely replaces the water that is normally used during the dyeing cycle, greatly reducing its use. What is more, the naturally occurring binding elements inside the microorganisms fix the pigments to the yarn without the use of chemicals.

THE NATURAL COLOURS

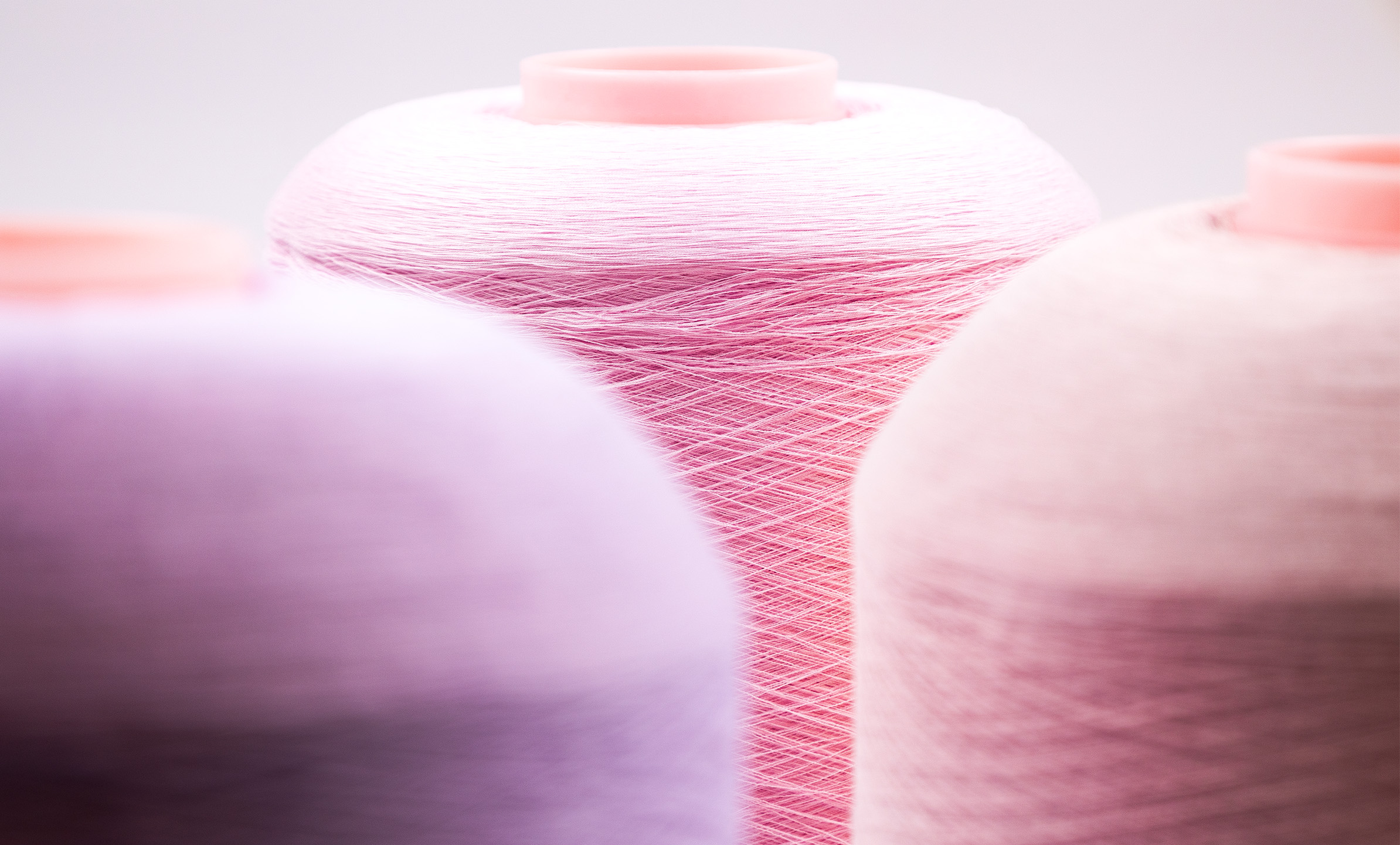

The “Exteria” project featured the use of two bacterial strains that produce different colours depending on the dyeing parameters and the chosen fibres:

- The first pigment is commonly found in soil and deep-sea sediments. ALBINI_next has dyed a beige colour onto cotton and a camel colour onto wool with this bacterial strain.

- The second pigment was first discovered as a contaminant in the silk production process. It was found on cocoons that had dark spots on them which could not be washed. With this pigment, which provides a brilliant purple colour, ALBINI_next has dyed 100% cotton yarns.

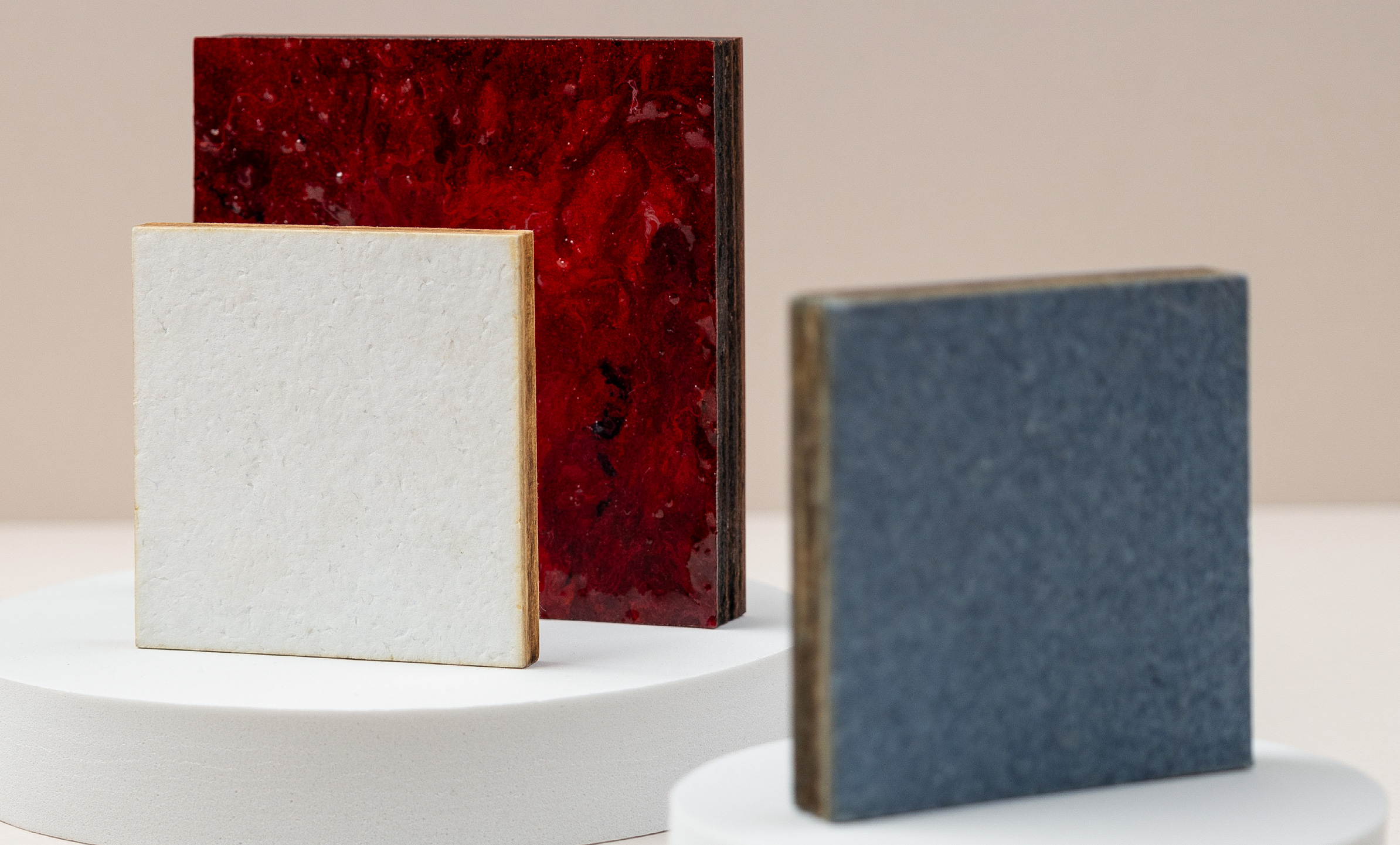

THE FABRICS

Once the yarns were dyed, the Albini Group dealt with the weaving and finishing process of the fabrics, always maintaining the highest standards of sustainability, and finally conducting tests to ensure colour quality and performance.

The result is responsibly dyed fabrics without the use of harmful chemicals.

The “Exteria” pilot project has thus validated the Colorifix technology applied to the dyeing of yarns on an industrial scale, thanks to the know-how of ALBINI_next and the fundamental support of the Kering’s MIL.

The next goal of this synergy is to take the project to an even broader industrial scale, able to satisfy market demands and bring about a radical change in the fashion industry.