An.Ti.Co.

YARNS FROM NATURALLY COLOURED COTTONS

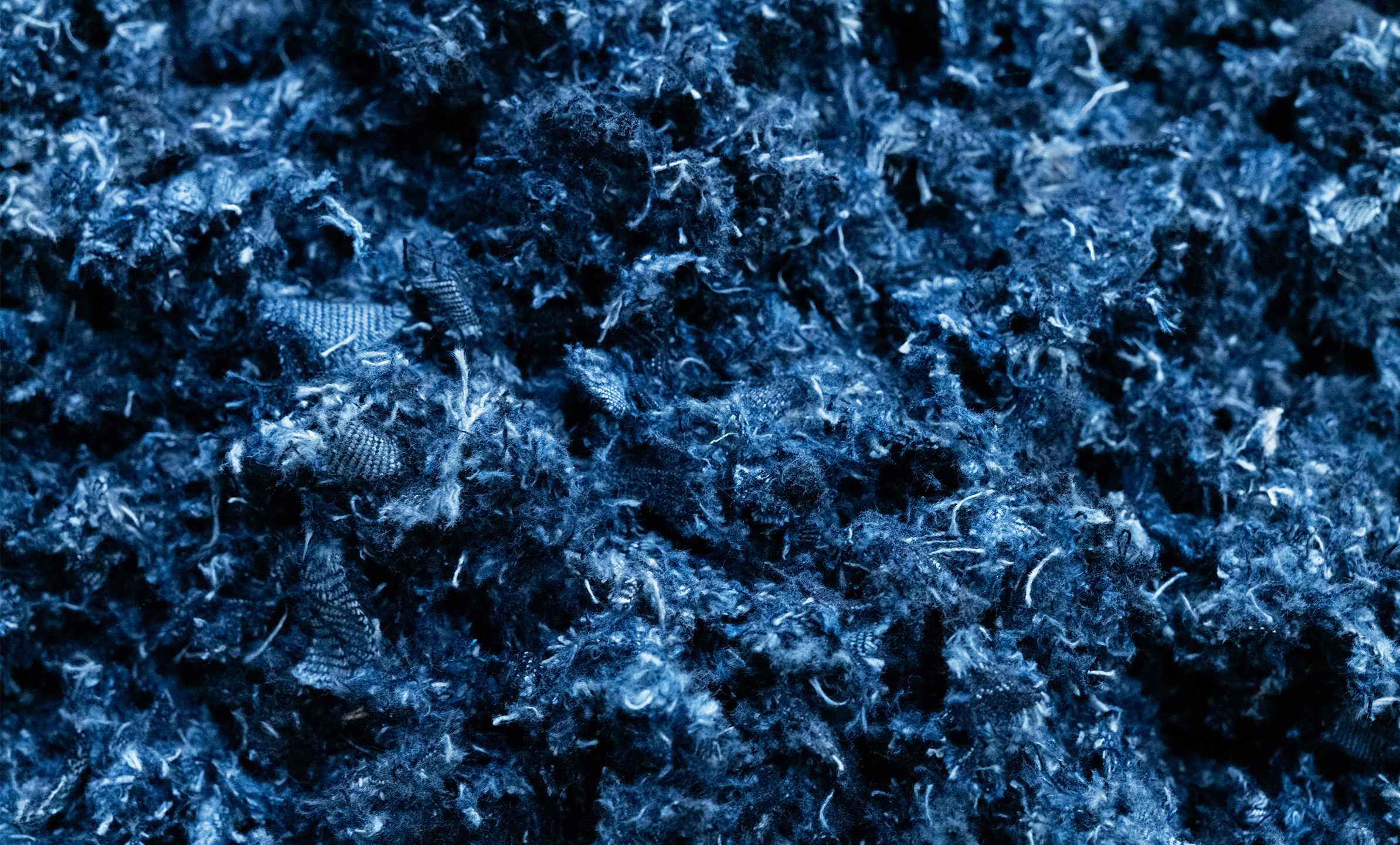

ALBINI_next studied the development of yarns made from cottons that grow with a natural colouring. The An.Ti.Co. (Ancient Times Cotton) project, originating in collaboration with Natural Hue, called for the use of two types of coloured cotton: one brown and one green.

The original seeds that generated the project are the result of a cross between ancient cotton seeds, which have the distinctive trait of producing a coloured fibre, and a non-genetically modified white fibre PIMA cotton seed.

THE ORIGINS AND HISTORY

The colour of the cotton fibre is a genetically controlled feature. The full expression of the colour of the lint only takes place when the boll is opened completely, and the lint is exposed to sunlight. It therefore takes about a week for the lint to develop a completely natural colour. Naturally coloured cotton fibres have always existed and have been used by humans since antiquity. These wild seeds, however, have disadvantages in today’s industrial context as they have a short fibre, low resistance and toughness, and most importantly, a rather limited productivity rate.

For these reasons, during the latter half of the 20th century, in a worldwide context of standardisation and increased production combined with the advent of synthetic colours, the textile industry almost completely abandoned the use of coloured cotton fibres in favour of white fibres, which offer a superior quality and yield.

THE HYBRIDISATION OF ANCIENT SEEDS

To overcome the challenges presented by naturally coloured cottons, the cotton breeders at Natural Hue in Arizona have been working for more than 40 years on hybridising these ancient seeds with the objective of improving the processability of fibre in an industrial context. After a lengthy work of hybridisation and cross-pollination of different cottons, Natural Hue created the variants that were cultivated for the An.Ti.Co. project, meeting the demand of ALBINI_next’s search for alternative, natural dyes.

In fact, thanks to the use of coloured cotton, it is possible to avoid any type of dye.

By crossing with conventional PIMA cotton, the coloured fibres resulting from these hybridised seeds have become longer and more resistant, and their yield per hectare higher.

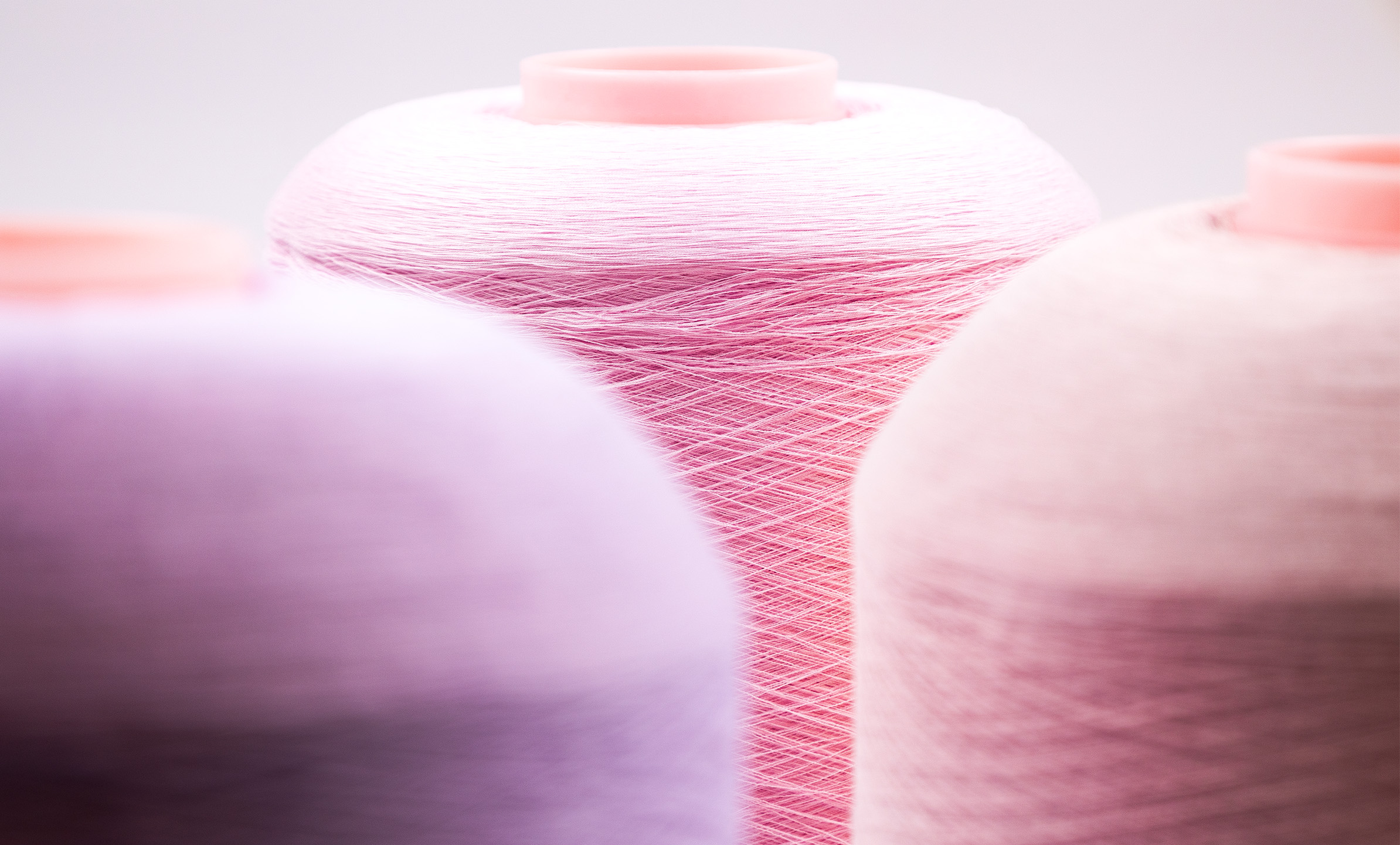

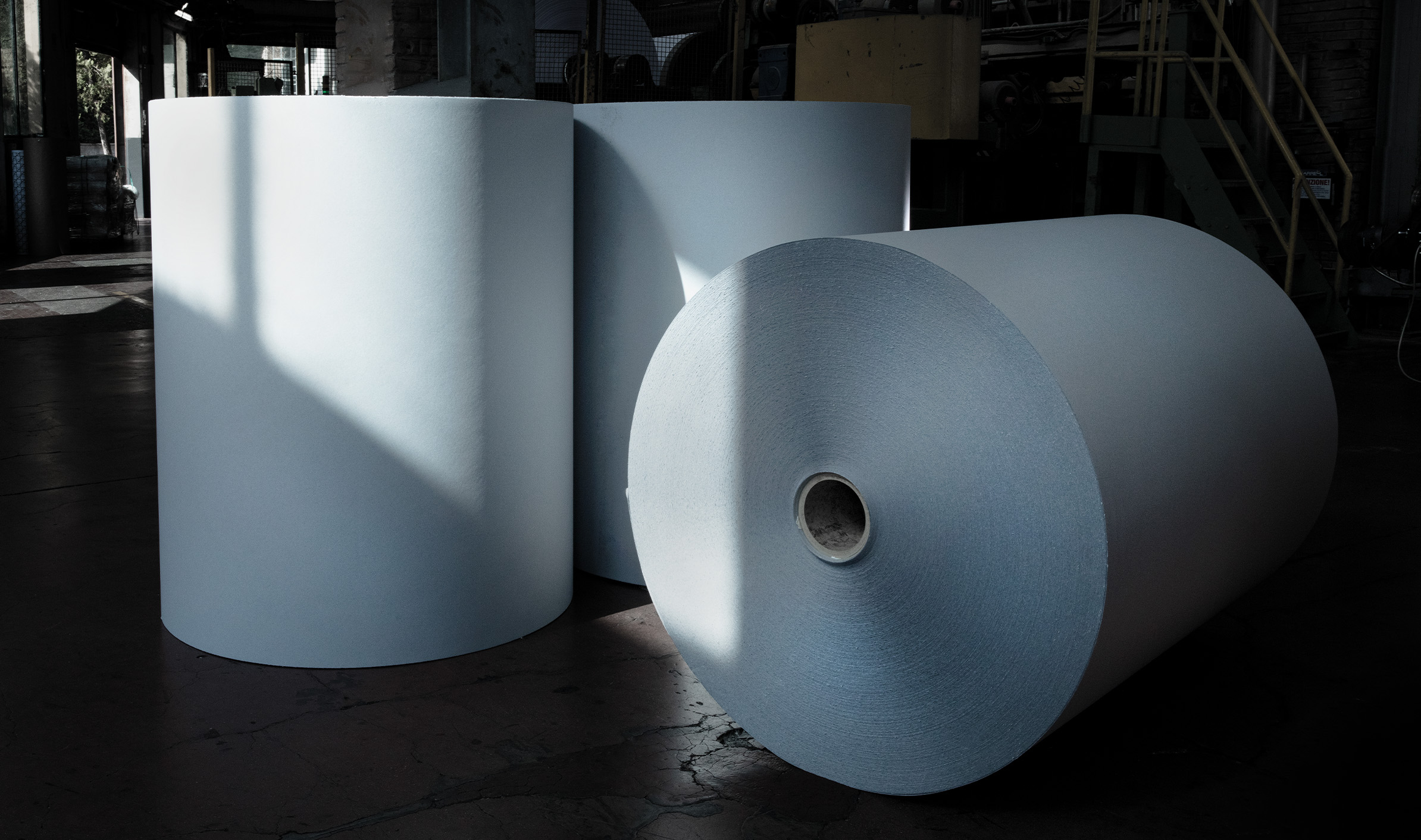

SPINNING AND WEAVING

Once this coloured cotton had been harvested, ALBINI_next relied on the Albini Group’s yarn division, ICA Yarns, to process these fibres. It resulted in the production of yarns with two different counts (30/1 ne and 10/1 ne) for each of the colours (brown and green).

Finally, these yarns were used by Albini Group brands to bring into being several of the fabrics in their collections, which have been able to accentuate the age-old natural beauty of these special cottons.